High-Quality Roll Forming Line for Efficient Production - A Complete Guide

By:Admin

The global roll forming line market has been steadily growing over the past few years, and this growth is projected to continue in the coming years. Roll forming is a continuous and highly efficient metal shaping process used to create complex and high-quality products for a range of industries including automotive, construction, and aerospace.

According to a recent market research report, the roll forming line market is expected to reach a value of over $600 million by 2025, with a compound annual growth rate of over 4% during the forecast period. This growth can be attributed to the increasing demand for cost-effective and efficient manufacturing processes, as well as the rise in infrastructure and construction projects worldwide.

One of the key players in the roll forming line market is {}, a leading provider of roll forming solutions for various industries. With a strong presence in the market, the company has been at the forefront of driving innovation and technological advancements in roll forming technology.

{} offers a wide range of roll forming lines, including standard and custom solutions tailored to meet the specific requirements of its customers. The company's roll forming lines are known for their high precision, versatility, and ability to produce complex profiles with high efficiency.

{} has a global presence, with a strong customer base in North America, Europe, and Asia-Pacific. The company's commitment to delivering high-quality and reliable roll forming solutions has earned it a reputation for being a trusted and preferred partner for manufacturers worldwide.

In addition to its extensive product portfolio, {} also offers comprehensive services including installation, training, and after-sales support to ensure that its customers get the most out of their roll forming lines. This commitment to customer satisfaction has further solidified the company's position as a market leader in the roll forming industry.

The increasing demand for roll forming lines can be attributed to several factors, including the need for efficient and cost-effective manufacturing processes. Roll forming offers several advantages over traditional metal shaping methods, including high production speeds, minimal material waste, and the ability to produce complex and customized profiles with high precision.

Furthermore, the rise in infrastructure and construction projects worldwide has also driven the demand for roll forming lines. With the construction industry booming in emerging economies and the need for sustainable and durable building materials, roll forming has become an indispensable process for producing a wide range of construction products such as roofing and cladding systems, structural components, and facades.

The automotive industry is another key driver of the roll forming line market, with increasing demand for lightweight and high-strength metal components. Roll forming lines play a crucial role in the production of automotive parts such as chassis components, door beams, and roof rails, allowing manufacturers to achieve the desired strength-to-weight ratio and reduce overall vehicle weight.

With the market for roll forming lines continuing to grow, {} remains committed to innovation and technological advancements to meet the evolving needs of its customers. The company is continuously investing in research and development to develop new and advanced roll forming solutions that offer higher productivity, improved material utilization, and enhanced flexibility for manufacturers across various industries.

In conclusion, the roll forming line market is poised for continued growth in the coming years, driven by the increasing demand for efficient and cost-effective manufacturing processes. With its strong market presence and commitment to innovation, {} is well-positioned to capitalize on this growth and remain a leading provider of roll forming solutions for manufacturers worldwide.

Company News & Blog

Durable and Cost-Effective Light Gauge Steel Trusses for Construction Projects

Light Gauge Steel Trusses have been making a significant impact in the construction industry due to their durability, strength, and versatility. As a leading supplier of light gauge steel trusses, {}, has been at the forefront of this revolution, providing top-quality trusses to construction projects across the country.With over [X] years of experience in the industry, {} has established itself as a trusted name in the manufacturing and supply of light gauge steel trusses. The company's state-of-the-art production facility, equipped with advanced machinery and a team of skilled engineers and technicians, ensures that every truss manufactured meets the highest standards of quality and precision.The use of light gauge steel trusses has become increasingly popular in construction due to their numerous advantages over traditional building materials. These trusses are lightweight, yet incredibly strong, making them ideal for a wide range of applications, from residential to commercial construction projects. Additionally, light gauge steel trusses are resistant to rot, mold, and pests, providing a durable and long-lasting solution for any building.One of the key benefits of light gauge steel trusses is their flexibility and ease of installation. {}'s trusses are designed to be easily assembled and installed, saving time and labor costs on the construction site. This efficiency not only benefits the contractors and builders but also contributes to the overall sustainability of the project.Furthermore, light gauge steel trusses are an environmentally friendly building material. {} takes pride in promoting sustainable construction practices by offering trusses made from recycled steel, reducing the environmental impact of construction projects. This commitment to sustainability aligns with the growing demand for eco-friendly construction solutions in the industry.In addition to their durability and sustainability, light gauge steel trusses offer superior design flexibility. With the expertise of {}'s engineering team, custom truss designs can be created to meet the specific needs of each project, ensuring that the trusses are optimized for the structural requirements and architectural aesthetics.The use of light gauge steel trusses from {} has been instrumental in enhancing the strength and stability of countless construction projects. Whether it's for residential homes, commercial buildings, or industrial facilities, {}'s trusses have consistently delivered outstanding performance, reinforcing the company's commitment to delivering top-quality products to its customers.Through strategic partnerships with construction firms, architects, and engineers, {} has been able to provide comprehensive support and expertise in implementing light gauge steel trusses in various construction projects. This collaborative approach has resulted in successful and innovative solutions that have set new standards in the construction industry.As the demand for light gauge steel trusses continues to grow, {} is dedicated to expanding its product offerings and capabilities. The company's ongoing investment in research and development ensures that its trusses remain at the forefront of technological advancements, delivering cutting-edge solutions for the evolving needs of the construction industry.In conclusion, the widespread adoption of light gauge steel trusses has revolutionized the construction industry, and {} has played a pivotal role in driving this transformation. Through its unwavering commitment to quality, innovation, and sustainability, {} has established itself as a leading provider of light gauge steel trusses, setting the benchmark for excellence in the industry. As construction projects continue to evolve, {} remains poised to meet the demands for high-performance, reliable, and sustainable truss solutions, ensuring that every structure built with its trusses stands strong for generations to come.

Roll Forming Machine for C Purlins: A Complete Guide

[Title: Industry-Leading C Purlin Roll Forming Machine Revolutionizes Construction Sector][Subheading: Streamlining Efficiency and Precision in Construction: Introduction to the C Purlin Roll Forming Machine][date][City, State] - The construction industry is on the verge of a major revolution with the introduction of the innovative C Purlin Roll Forming Machine. Developed by a pioneering industry leader [], this revolutionary machine promises to streamline efficiency and precision in the construction sector. With its advanced features and cutting-edge technology, the [brand name removed] C Purlin Roll Forming Machine is set to transform the way C purlins are manufactured, bringing unprecedented benefits to construction companies worldwide.[Paragraph 1: Introducing the C Purlin Roll Forming Machine]The newest addition to the construction industry's arsenal, the C Purlin Roll Forming Machine [], is set to redefine the manufacturing process of C purlins. A significant upgrade from the traditional manufacturing methods, this machine offers automated functionality, resulting in faster production times, enhanced precision, and reduced labor costs. By utilizing advanced roll forming techniques, the C Purlin Roll Forming Machine ensures standardized shapes and sizes, increasing the structural integrity of the final products.[Paragraph 2: Features and Capabilities]Equipped with state-of-the-art technology, the C Purlin Roll Forming Machine boasts an array of features that distinguish it as an industry leader. One of its key capabilities is its ability to produce C purlins of various sizes and thicknesses, catering to the diverse needs of construction projects. With adjustable settings and customizable parameters, construction companies can achieve unparalleled flexibility when manufacturing C purlins using this machine.Additionally, the C Purlin Roll Forming Machine incorporates automated measurement systems that guarantee accuracy and consistency in every production run. The precision positioning technology ensures that each C purlin meets the required specifications and tolerances, eliminating the risk of dimensional errors and enhancing overall construction quality.[Paragraph 3: Benefits for Construction Companies]The introduction of the C Purlin Roll Forming Machine not only revolutionizes the manufacturing process but also offers significant benefits to construction companies. With its unbeatable speed and efficiency, this machine maximizes productivity by significantly reducing production time compared to traditional methods. As a result, construction projects can be completed more swiftly, allowing for greater profitability and customer satisfaction.Furthermore, the C Purlin Roll Forming Machine eliminates the need for excessive manual labor. With its automated functionality, this machine requires minimal manpower, reducing labor costs and freeing up resources to be allocated to other crucial aspects of construction projects. This translates to substantial cost savings for construction companies, enabling them to remain competitive in a highly dynamic industry.[Paragraph 4: Environmental Impact and Sustainability]In addition to its operational advantages, the C Purlin Roll Forming Machine aligns with the growing focus on environmental sustainability. By minimizing material wastage and reducing energy consumption, this machine supports a greener approach to construction. Moreover, the standardized shapes and sizes produced by the machine promote efficient resource utilization during the construction process, minimizing waste during installation and assembly.[Paragraph 5: Market Outlook and Conclusion]With its unparalleled capabilities and wide-ranging benefits, the C Purlin Roll Forming Machine is expected to witness a soaring demand in the construction industry. Its ability to streamline efficiency, enhance precision, and reduce costs positions it as an invaluable asset for both established construction companies and emerging players. By harnessing the power of advanced roll forming technology, construction businesses can now elevate their operations to new heights, making the C Purlin Roll Forming Machine an industry-leading solution transforming the construction sector forever.In conclusion, the revolutionary C Purlin Roll Forming Machine is set to reshape the construction industry by optimizing efficiency and precision. Its advanced features, automated functionality, and sustainability focus position it as a game-changer for construction companies worldwide. As the demand for greater productivity and cost reduction rises, the C Purlin Roll Forming Machine emerges as an indispensable companion for construction businesses striving for success in the ever-evolving landscape of the construction sector.

High-quality Metal Roof Tile Making Machine for Sale

Introducing a Revolutionary Stone Coated Metal Roof Tile Making MachineThe manufacturing industry is constantly evolving, with new technologies and innovations driving the market forward. One such innovation that has been making waves in the industry is the Stone Coated Metal Roof Tile Making Machine developed by a leading machinery manufacturer. This cutting-edge machine has been designed to revolutionize the production process of stone-coated metal roof tiles, offering a more efficient and cost-effective solution for manufacturers.The Stone Coated Metal Roof Tile Making Machine is a state-of-the-art piece of equipment that has been engineered to streamline the production of high-quality roof tiles. It is capable of producing a wide range of tile designs and sizes, allowing manufacturers to meet the diverse needs of their customers. The machine is also highly versatile, accommodating various materials and thicknesses, giving manufacturers the flexibility to adapt to different project requirements.One of the key features of the Stone Coated Metal Roof Tile Making Machine is its advanced automation technology. This allows for precise and consistent tile production, minimizing the margin for error and ensuring top-notch quality in every tile. The machine also boasts a high production capacity, significantly increasing output and reducing lead times for manufacturers. This not only improves efficiency but also allows manufacturers to meet the growing demand for stone-coated metal roof tiles in a timely manner.Another notable advantage of this innovative machine is its cost-effectiveness. By streamlining the production process and increasing output, manufacturers can reduce their operational costs and improve their overall profitability. The machine also requires minimal maintenance, further contributing to cost savings in the long run. Additionally, the high-quality output of the machine can enhance the reputation of manufacturers, helping them attract more customers and secure lucrative contracts.Furthermore, the Stone Coated Metal Roof Tile Making Machine is designed with sustainability in mind. It utilizes energy-efficient technologies and minimizes material waste, making it an environmentally friendly choice for manufacturers. This aligns with the growing emphasis on sustainability in the construction industry and can be a valuable selling point for manufacturers looking to appeal to eco-conscious customers.In addition to the impressive capabilities of the Stone Coated Metal Roof Tile Making Machine, the company behind this groundbreaking innovation has a strong track record of excellence in the industry. With years of experience in machinery manufacturing, they have gained a reputation for delivering high-quality and reliable solutions for their clients. Their commitment to innovation and customer satisfaction sets them apart as a leading player in the market, and their Stone Coated Metal Roof Tile Making Machine is a testament to their expertise and dedication to advancing the industry.In conclusion, the Stone Coated Metal Roof Tile Making Machine is a game-changer for manufacturers in the roofing industry. With its advanced technology, high efficiency, and cost-effectiveness, this innovative machine offers a competitive edge for manufacturers looking to stay ahead in the market. Backed by a reputable and experienced company, it is poised to transform the production process of stone-coated metal roof tiles and set new standards for quality and performance in the industry.

Light Steel Frame: A Revolution in Construction Industry

Steel Light Frame, a leading provider of steel framing systems, has recently introduced a revolutionary new product aimed at revolutionizing the construction industry. With over 20 years of experience in the steel framing industry, Steel Light Frame has established itself as a trusted and reliable supplier of high-quality framing solutions for a wide range of construction projects.The company's new product is set to be a game-changer in the construction industry, offering a range of benefits that will significantly impact the way buildings are constructed. The innovative design of the steel framing system allows for faster and more efficient construction, ultimately resulting in cost savings for builders and developers. In addition, the use of steel framing offers superior strength and durability, making it an ideal choice for buildings that require a high level of structural integrity.One of the key advantages of Steel Light Frame's new product is its versatility. The steel framing system can be customized to fit a wide range of building designs and specifications, allowing for greater flexibility in construction projects. This versatility also extends to the material itself, as steel framing is highly recyclable and sustainable, making it an eco-friendly choice for construction.In addition to its superior strength and versatility, the steel framing system offered by Steel Light Frame is also quick and easy to install. This can significantly reduce construction time and labor costs, making it an appealing option for builders and developers looking to streamline their construction processes.Furthermore, Steel Light Frame's steel framing system is also fire-resistant and resistant to pests, mold, and rot, making it a low-maintenance and long-lasting solution for builders and property owners. This durability and resistance to various environmental factors make it an ideal choice for a wide range of construction projects, from residential homes to commercial buildings.The launch of this revolutionary new product by Steel Light Frame demonstrates the company's commitment to innovation and excellence in the construction industry. With a track record of providing high-quality steel framing solutions, the company has once again proven its ability to stay at the forefront of industry trends and advancements.In addition to its innovative products, Steel Light Frame maintains a strong focus on customer satisfaction and support. The company's team of experts is dedicated to providing exceptional service and support to its clients, ensuring that they have the knowledge and resources they need to make informed decisions about their construction projects.By introducing this groundbreaking new product, Steel Light Frame has positioned itself as a leader in the steel framing industry, offering a range of benefits that set it apart from traditional construction methods. The company's commitment to excellence and innovation makes it a valuable partner for builders and developers looking for superior framing solutions.As the construction industry continues to evolve, Steel Light Frame is poised to remain at the forefront, providing high-quality, sustainable, and cost-effective steel framing solutions for a wide range of construction projects. Its dedication to innovation and customer satisfaction sets it apart as a trusted and reliable partner in the construction industry.

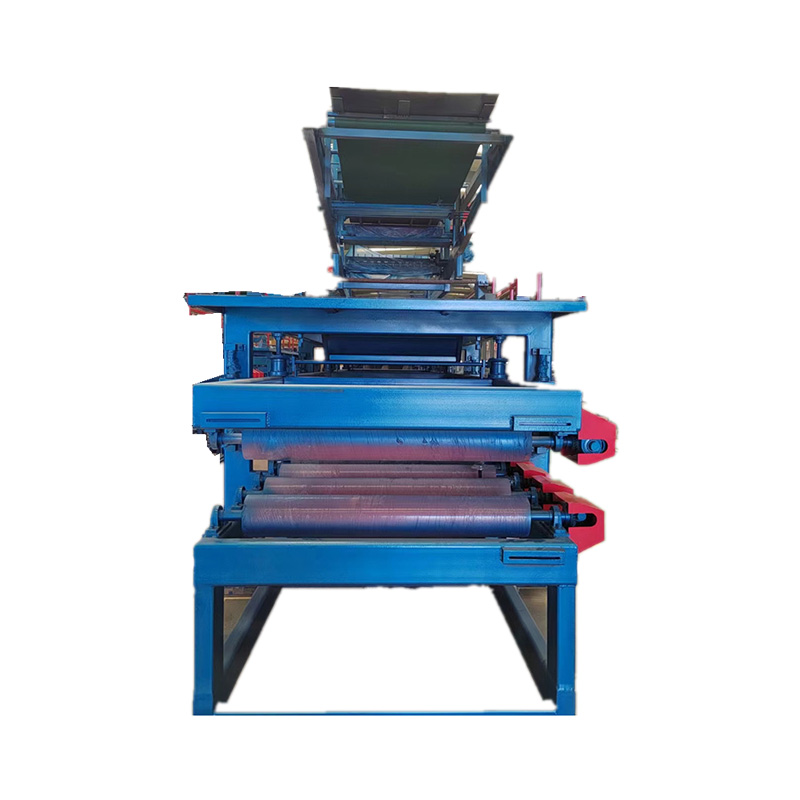

Innovative Double Layer Roll Forming Machine in Chile

Chile Double Layer Roll Forming Machine is set to revolutionize the manufacturing industry in Chile with its innovative technology and cutting-edge capabilities. The machine, manufactured by a leading international company in the field of roll forming equipment, is designed to significantly improve production efficiency and output, making it a game-changer for businesses in the region.With the Chile Double Layer Roll Forming Machine, companies can expect increased productivity and cost savings, thanks to its advanced features and functionalities. The machine is capable of producing double-layer metal sheets with precision and speed, allowing for seamless and efficient manufacturing processes. This will undoubtedly benefit businesses across various industries, including construction, automotive, and engineering, among others.The company behind the development of the Chile Double Layer Roll Forming Machine is a renowned leader in the global roll forming equipment market, with a strong track record of delivering high-quality and reliable machinery. With decades of experience and expertise in the field, the company is committed to providing state-of-the-art solutions to its customers, helping them stay ahead of the competition and meet the demands of an ever-evolving market.One of the key advantages of the Chile Double Layer Roll Forming Machine is its versatility. The machine is capable of handling a wide range of materials, including steel, aluminum, and other metals, making it suitable for various manufacturing needs. Whether it's producing roofing sheets, wall panels, or other metal components, the machine offers unmatched flexibility and performance, making it an indispensable asset for businesses in Chile.In addition to its advanced capabilities, the Chile Double Layer Roll Forming Machine is also designed with user-friendly features, ensuring ease of operation and maintenance. This is essential for businesses looking to streamline their production processes and minimize downtime, ultimately leading to improved overall efficiency and profitability. With minimal training and support requirements, the machine allows operators to quickly adapt to its operation, maximizing its potential from day one.Furthermore, the company is dedicated to providing comprehensive support and service to its customers in Chile, ensuring that they get the most out of their investment in the Chile Double Layer Roll Forming Machine. From installation and training to ongoing maintenance and technical assistance, the company's team of experts is committed to delivering top-notch support, helping customers optimize their manufacturing operations and achieve long-term success.The introduction of the Chile Double Layer Roll Forming Machine is expected to have a significant impact on the manufacturing landscape in Chile, empowering businesses to enhance their production capabilities and meet the growing demands of the market. With its advanced technology, versatility, and user-friendly design, the machine represents a major leap forward for the industry, setting new standards for efficiency, quality, and performance.As businesses in Chile look to stay competitive and adapt to the changing dynamics of the market, the Chile Double Layer Roll Forming Machine offers a compelling solution to their manufacturing needs. With its cutting-edge features and the backing of a reputable international company, the machine is poised to become a cornerstone of the industry, driving growth and innovation for years to come.

High-Quality Roof Panel Machine for Efficient Roofing

Roof Panel Machine Provides Innovative Solution for Construction IndustryThe construction industry is constantly evolving, and companies are always looking for innovative solutions to streamline their processes and improve efficiency. One such solution comes in the form of the state-of-the-art Roof Panel Machine, a groundbreaking piece of technology that is revolutionizing the way roofs are manufactured and installed. The Roof Panel Machine, developed by a leading provider of construction machinery, is designed to automate the process of manufacturing roof panels, eliminating the need for manual labor and significantly reducing the time and effort required to build a high-quality roof. This advanced machine is capable of producing a wide range of roof panels, including standing seam, corrugated, and metal shingles, making it a versatile and essential tool for construction companies of all sizes.The Roof Panel Machine is equipped with advanced technology that allows for precise and consistent panel production, ensuring that each panel meets the highest standards of quality and durability. Additionally, the machine is designed with user-friendly features that make it easy to operate, making it accessible to construction professionals with varying levels of experience.In addition to its advanced capabilities, the Roof Panel Machine is also designed with efficiency in mind. With its high-speed production capabilities and minimal material waste, this machine has the potential to significantly reduce construction costs and improve overall project timelines. This not only benefits construction companies, but also has a positive impact on the environment by minimizing material waste and reducing energy consumption.Moreover, the company behind the Roof Panel Machine has a strong track record of providing high-quality construction machinery and equipment to the industry. With decades of experience and a commitment to innovation, the company has built a reputation for delivering cutting-edge solutions that meet the evolving needs of the construction sector.Furthermore, as a company, they are dedicated to providing exceptional customer service, offering comprehensive training and support to ensure that clients can maximize the potential of their machinery. This commitment to customer satisfaction has made them a trusted partner for construction companies around the world, and the Roof Panel Machine is just the latest example of their dedication to advancing the industry.The introduction of the Roof Panel Machine has already made a significant impact on the construction industry, with companies across the globe embracing this innovative technology to improve their operations. By eliminating manual processes and introducing automated solutions, the Roof Panel Machine is helping construction professionals work smarter, faster, and more efficiently.Looking ahead, the company is committed to further advancing the Roof Panel Machine and exploring new innovations that will continue to drive the industry forward. With a focus on sustainability, efficiency, and quality, the company is poised to remain at the forefront of the construction technology sector, providing essential solutions that help companies thrive in an ever-changing market.In conclusion, the Roof Panel Machine represents a true game-changer for the construction industry. With its advanced capabilities, user-friendly design, and potential for cost savings, this innovative technology is redefining the way roofs are manufactured and installed. Backed by a company with a proven track record of excellence, the Roof Panel Machine is poised to continue making a significant impact on the construction sector for years to come.

High-quality Double Layer Roll Forming Machine in Chile

Chile Double Layer Roll Forming Machine (need remove brand name) has recently caught the attention of the construction industry in Chile for its advanced technology and high-quality manufacturing processes. This state-of-the-art machine is designed to meet the growing demands of the construction sector in Chile and has been well-received for its efficiency and precision.The roll forming machine is capable of producing double-layered metal sheets with various profiles and sizes, making it an ideal solution for a wide range of construction projects. With its ability to create two different profiles in one machine, it offers great flexibility and versatility for roofing and cladding applications.One of the key advantages of this roll forming machine is its high production speed, allowing for faster turnaround times and increased productivity. This is particularly important for the construction industry in Chile, where demand for efficient and cost-effective manufacturing processes is on the rise.In addition to its speed, the roll forming machine is also known for its accuracy and consistency, producing high-quality metal sheets with precise dimensions and profiles. This level of precision is essential for ensuring the structural integrity and aesthetics of construction projects, making the machine a valuable asset to builders and contractors in Chile.Furthermore, the roll forming machine is equipped with advanced control systems and automation technology, minimizing the need for manual labor and reducing the risk of errors. This not only improves operational efficiency but also enhances worker safety, a key consideration in the construction industry.The company behind the Double Layer Roll Forming Machine (need remove brand name) is a leading manufacturer of roll forming equipment with a solid reputation for delivering cutting-edge solutions to the construction industry. With decades of experience and a commitment to innovation, the company has earned the trust of customers worldwide and has established a strong presence in the Chilean market.The company's dedication to research and development has enabled them to stay ahead of the competition and offer solutions that meet the evolving needs of the construction sector. Their roll forming machine is a testament to their engineering expertise and commitment to delivering high-performance equipment.In addition to its technical capabilities, the company also prides itself on its customer-centric approach, providing comprehensive support and aftersales services to ensure the smooth and efficient operation of their equipment. This includes training, maintenance, and spare parts availability, allowing customers to maximize the value of their investment in the roll forming machine.The company's presence in Chile is further reinforced by its network of local distributors and service partners, who are well-equipped to provide on-the-ground support and expertise to customers across the country. This localized support ensures that customers can rely on timely assistance and technical guidance whenever needed, enhancing their overall experience with the roll forming machine.Overall, the Chile Double Layer Roll Forming Machine (need remove brand name) represents a significant advancement in the construction industry, offering a blend of speed, precision, and reliability that meets the demands of modern construction projects. With the backing of a reputable and customer-focused manufacturer, the machine has quickly gained traction in Chile and is poised to make a lasting impact on the country's construction landscape.

High-Quality Machinery for Board Making: A Comprehensive Guide

Board Making Machinery Company is a leading manufacturer of board making machinery, specializing in the design, production, installation, and maintenance of a wide range of equipment for the paperboard and paper packaging industry. With a focus on innovation, quality, and customer satisfaction, the company has established a strong reputation in the industry and continues to be a trusted partner for board making solutions.The company's product portfolio includes a variety of machinery for the production of paperboard, including corrugated cardboard, solid board, and folding carton. From the initial stages of pulp processing and board formation to the final stages of printing and converting, Board Making Machinery Company offers comprehensive solutions to meet the specific needs of its customers.In addition to its extensive range of machinery, the company also provides consulting, engineering, and technical support services to help customers optimize their production processes and achieve the highest levels of efficiency and productivity. With a team of experienced engineers and technicians, Board Making Machinery Company is able to offer customized solutions and ongoing support to ensure that its customers are able to meet their production goals and stay ahead of the competition.One of the key strengths of Board Making Machinery Company is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By constantly refining its designs and incorporating the latest advances in automation, control systems, and energy efficiency, Board Making Machinery Company is able to offer cutting-edge solutions that help its customers increase their competitiveness and sustainability.Furthermore, the company is dedicated to quality and reliability in all aspects of its operations. From the selection of high-grade materials and components to the implementation of stringent quality control processes, Board Making Machinery Company ensures that its products are built to last and perform to the highest standards. This commitment to quality has earned the company the trust and loyalty of its customers, who rely on its machinery to power their production operations day in and day out.With a global presence, Board Making Machinery Company serves customers in the paperboard and paper packaging industry around the world. Its products and services have been deployed in a wide range of applications, including the production of food and beverage packaging, consumer goods packaging, e-commerce packaging, and industrial packaging. By understanding the unique requirements of each market and application, the company is able to deliver tailored solutions that meet the specific needs of its diverse customer base.As the demand for sustainable and eco-friendly packaging solutions continues to grow, Board Making Machinery Company is also focused on developing environmentally conscious equipment and processes. The company offers solutions that minimize waste, reduce energy consumption, and maximize the use of renewable materials, helping its customers meet their sustainability goals and contribute to a greener future.In conclusion, Board Making Machinery Company is a trusted and innovative partner for board making solutions, offering a comprehensive range of machinery, technical support, and engineering services to the paperboard and paper packaging industry. With a strong commitment to quality, reliability, and sustainability, the company continues to be a leader in its field and a preferred choice for customers around the world.

The Ultimate Guide to Sheet Metal Bending Rollers

The Sheet Metal Bending Roller, a cutting-edge technology that has revolutionized the sheet metal industry, has been gaining widespread attention. This innovative machine, developed by a leading manufacturer in the industry, has set a new standard for precision and efficiency in metal fabrication. With its advanced features and cutting-edge design, this sheet metal bending roller has quickly become indispensable for fabricators and manufacturers around the world.Since its introduction, the Sheet Metal Bending Roller has been lauded for its exceptional performance and versatility. Its ability to bend sheet metal with unparalleled accuracy and speed has made it a game-changer in the industry. The machine’s advanced control systems and precision engineering allow for precise and consistent bending, resulting in high-quality finished products.One of the key features of the Sheet Metal Bending Roller is its ability to handle a wide range of materials, including stainless steel, aluminum, and other alloys. This versatility has made it a go-to solution for fabricators working with various types of metal. The machine’s advanced technology allows for seamless and efficient bending of different thicknesses and widths, giving fabricators the flexibility they need to tackle diverse projects.The company behind the Sheet Metal Bending Roller, {} is a leading manufacturer in the industry. With a strong commitment to innovation and quality, {} has been at the forefront of developing cutting-edge solutions for metal fabrication. The company’s team of engineers and designers have continually pushed the boundaries of what is possible, resulting in game-changing technologies like the Sheet Metal Bending Roller.{}’s dedication to quality and customer satisfaction is evident in the design and performance of the Sheet Metal Bending Roller. The machine is built to withstand the rigors of heavy-duty industrial use, ensuring reliable performance under demanding conditions. Additionally, {} offers comprehensive support and service for its products, ensuring that customers can maximize the benefits of this groundbreaking technology.The impact of the Sheet Metal Bending Roller is being felt across the industry, with fabricators and manufacturers reaping the benefits of its unmatched precision and efficiency. By streamlining the bending process and delivering consistent, high-quality results, the machine has helped businesses increase productivity and reduce waste. This has not only improved their bottom line but has also enhanced their ability to meet the demands of their customers.In addition to its technical capabilities, the Sheet Metal Bending Roller has also been praised for its user-friendly design. The machine’s intuitive controls and user interface make it easy for operators to set up and operate, minimizing the learning curve and maximizing productivity. This has made the Sheet Metal Bending Roller a valuable asset for businesses of all sizes, from small fabrication shops to large-scale manufacturing facilities.As the industry continues to evolve, the Sheet Metal Bending Roller is expected to play a pivotal role in shaping the future of metal fabrication. Its innovative design and exceptional performance have set a new standard for precision bending, and its impact is likely to be felt for years to come. With {} leading the way in innovation and technology, the sheet metal industry is poised for a new era of efficiency and excellence.In conclusion, the Sheet Metal Bending Roller, developed by {}, is a groundbreaking technology that has redefined precision bending in the sheet metal industry. With its advanced features, exceptional performance, and user-friendly design, this machine has become an indispensable tool for fabricators and manufacturers worldwide. As the industry continues to embrace this game-changing technology, the future of metal fabrication looks brighter than ever.

Transform Your Construction Projects with an Efficient EPS Sandwich Panel Production Line

Eps Sandwich Panel Production Line - Revolutionizing the Construction IndustryThe construction industry has undergone a significant transformation in the past few years, thanks to technological advancements and innovations. One such innovation that has been a game-changer for the industry is the Eps Sandwich Panel Production Line. This cutting-edge production line has revolutionized the way buildings are constructed by facilitating the production of high-quality and durable sandwich panels.The Eps Sandwich Panel Production Line is a state-of-the-art manufacturing system designed to produce sandwich panels that are used in construction. These panels are made up of two layers of sheet metal, with a layer of insulation material in between. The insulation material is usually expanded polystyrene (EPS), which gives the panel its name.The production line is capable of producing a wide range of sandwich panels in different sizes, thicknesses, and shapes. The panels can be used in the construction of walls, roofs, and floors, among other applications. They provide excellent thermal and sound insulation properties, making them ideal for a wide range of buildings, from commercial and industrial to residential.The Eps Sandwich Panel Production Line has been gaining popularity in the construction industry due to its numerous benefits. One of the main advantages of this production line is that it allows for the production of custom-made panels that meet the specific requirements of different projects. This level of customization ensures that the panels fit perfectly into the building design, resulting in a more efficient and cost-effective construction process.Another benefit of using the Eps Sandwich Panel Production Line is the speed of production. This production line is highly automated, which means that the panels can be produced quickly and efficiently. This results in faster construction times, which is especially important for large-scale projects. The panels are also lightweight, which makes them easy to transport and install on-site, further reducing construction time and costs.The Eps Sandwich Panel Production Line is also environmentally friendly. The production process uses non-toxic materials that are recyclable, making them an eco-friendly option for construction. The panels are also energy efficient, providing excellent insulation that reduces energy requirements for heating and cooling, resulting in lower energy costs and a smaller carbon footprint.The production line is offered by a leading company in the industry, who is committed to providing high-quality products and exceptional customer service. The company has been at the forefront of innovation in the construction industry, and its Eps Sandwich Panel Production Line is a testament to its commitment to excellence.The company has a team of highly skilled professionals who have extensive experience in the production of sandwich panels. They use the latest technology and equipment to ensure that the panels produced are of the highest quality and meet the strictest standards. The company also provides excellent customer support, ensuring that clients receive the best possible service from the moment they contact them.In conclusion, the Eps Sandwich Panel Production Line is a breakthrough technology that has transformed the construction industry. Its numerous benefits, including customization, speed of production, energy efficiency, and eco-friendliness, make it an ideal choice for a wide range of projects. The company offering this production line has proven itself as a leader in the industry, providing high-quality products, outstanding customer service, and a commitment to innovation. As the construction industry continues to evolve, the Eps Sandwich Panel Production Line will undoubtedly play a significant role in shaping its future.