Light Steel Frame Prefabricated House: A Modern and Efficient Housing Option

By:Admin

The Light Steel Frame Prefabricated House is a type of modern construction that involves the use of light gauge steel framing. This type of construction is known for its strength, durability, and versatility, making it an ideal choice for building residential and commercial properties. The use of light gauge steel framing in prefabricated housing has gained popularity in recent years due to its numerous benefits, including its ability to withstand extreme weather conditions, its resistance to pests and mold, and its energy efficiency.

One of the key features of Light Steel Frame Prefabricated House is its fast construction time. Unlike traditional construction methods, which can take months or even years to complete, prefabricated housing can be built in a matter of weeks. This is due to the use of standardized building components that are manufactured off-site and then assembled on-site, reducing construction time and labor costs. In addition to its quick construction time, prefabricated housing is also more cost-effective than traditional construction methods, making it an attractive option for homeowners and developers.

Another advantage of Light Steel Frame Prefabricated House is its sustainability. The use of light gauge steel framing in prefabricated housing reduces the need for natural resources, such as wood and concrete, making it a more environmentally friendly option. Additionally, prefabricated housing is designed to be energy efficient, with features such as insulation and energy-efficient windows and doors, reducing energy consumption and lowering utility costs for homeowners.

In addition to its sustainability, Light Steel Frame Prefabricated House is also designed to be customizable, allowing homeowners to create a unique and personalized living space. With a wide range of design options and finishes, homeowners can create a home that suits their individual needs and preferences, from the layout of the rooms to the exterior and interior finishes.

Light Steel Frame Prefabricated House is also gaining popularity due to its ability to withstand natural disasters, such as earthquakes and hurricanes. The use of light gauge steel framing provides superior strength and flexibility, making prefabricated housing a safe and durable option for homeowners in areas prone to natural disasters.

One company at the forefront of the Light Steel Frame Prefabricated House movement is {Company Name}. With a strong emphasis on innovation and sustainability, {Company Name} has been a pioneer in the development and implementation of prefabricated housing solutions. With a team of experienced architects, engineers, and designers, {Company Name} is dedicated to creating high-quality, custom-built prefabricated homes that meet the needs of modern homeowners.

{Company Name} offers a wide range of prefabricated housing options, from small, single-family homes to larger, multi-story buildings. With a focus on quality and efficiency, {Company Name} is committed to delivering environmentally friendly and cost-effective housing solutions that exceed the expectations of its clients.

In addition to its commitment to sustainability and innovation, {Company Name} also provides excellent customer service, ensuring that clients have a positive experience throughout the entire construction process. From the initial design phase to the final installation, {Company Name} works closely with its clients to ensure that their vision for their prefabricated home is brought to life.

As the demand for affordable, sustainable, and customizable housing solutions continues to grow, the Light Steel Frame Prefabricated House is poised to become a major player in the construction industry. With its numerous benefits, including its fast construction time, sustainability, and durability, prefabricated housing is a game-changer for homeowners and developers alike. And with companies like {Company Name} leading the way, the future of housing looks brighter than ever.

Company News & Blog

Innovative Tile Making Machine for Making Sandwich Tiles in the News

Sandwich Tile Making Machine Innovates the Construction IndustryThe construction industry has seen significant advancements in technology over the years, with the latest innovation being the introduction of the Sandwich Tile Making Machine by a leading manufacturing company. This revolutionary machine is set to streamline the production process of sandwich tiles, a popular construction material known for its durability and energy-efficient properties.With the global demand for sustainable building solutions on the rise, the Sandwich Tile Making Machine comes at a time when the construction industry is seeking more efficient and eco-friendly alternatives. These innovative machines are designed to manufacture sandwich tiles, which are composed of a layer of insulation material sandwiched between two layers of concrete or other binding materials. This construction method offers superior thermal performance, sound insulation, and fire resistance, making it an ideal choice for modern building projects.The Sandwich Tile Making Machine is equipped with advanced technology to ensure precision and consistency in the production of these specialized tiles. The machine is capable of producing a wide variety of tile sizes and designs, allowing for maximum flexibility to meet the diverse needs of construction projects. Furthermore, the automated nature of the machine significantly reduces labor costs and enhances productivity, making it an attractive investment for construction companies.The manufacturing company behind the Sandwich Tile Making Machine has a long-standing reputation for producing high-quality construction equipment and machinery. With a strong focus on innovation and sustainability, the company has been at the forefront of developing solutions that contribute to the advancement of the construction industry. Their commitment to research and development has led to the creation of the Sandwich Tile Making Machine, which is poised to make a significant impact on the way sandwich tiles are produced and used in construction.In addition to its technological advancements, the Sandwich Tile Making Machine also reflects the company's dedication to environmental sustainability. By promoting the use of energy-efficient building materials such as sandwich tiles, the machine aligns with the global efforts to reduce carbon emissions and enhance the overall environmental performance of buildings. This commitment to sustainability underscores the company's mission to create products that not only meet the highest standards of quality and performance but also have a positive impact on the environment.The introduction of the Sandwich Tile Making Machine is expected to have far-reaching implications for the construction industry. Its ability to streamline the production process and improve the quality of sandwich tiles will undoubtedly benefit construction companies and builders looking to incorporate sustainable building materials into their projects. Furthermore, the machine's efficiency and automation will contribute to cost savings and increased competitiveness within the industry.As the global construction industry continues to prioritize sustainable and energy-efficient building practices, the Sandwich Tile Making Machine represents a significant step towards meeting these objectives. Its advanced technology and environmental benefits position it as a game-changer in the production of sandwich tiles, offering a reliable and efficient solution for the evolving needs of the construction sector. With its introduction, the Sandwich Tile Making Machine is set to revolutionize the way sandwich tiles are manufactured and pave the way for a more sustainable future in construction.

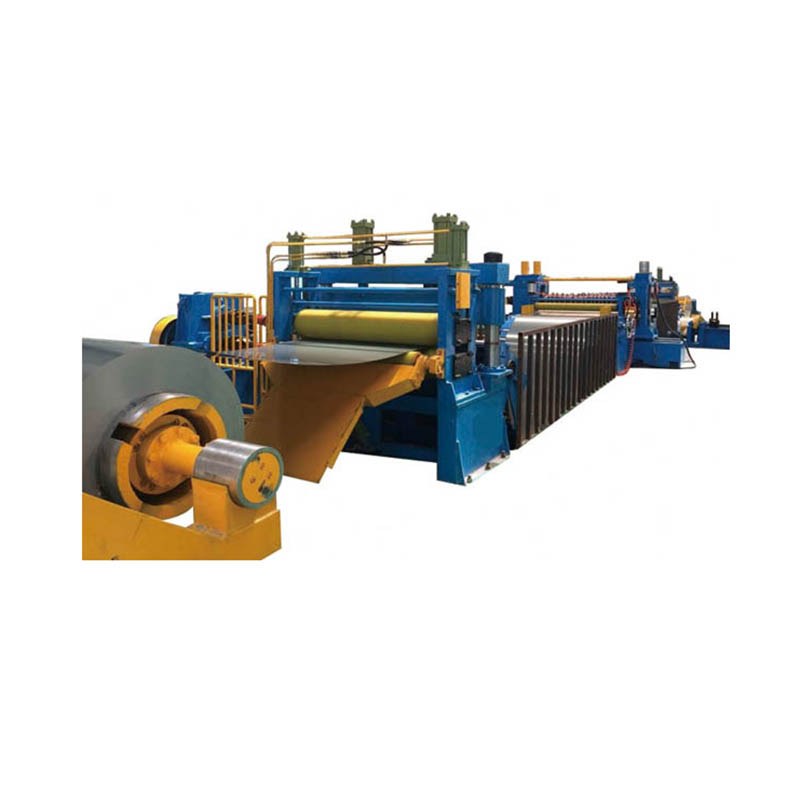

The complete guide to metal roll forming machines

Metal Roll Forming Machine Boosts Production Efficiency and Precision for [][City, State] - The demand for metal roll forming technology has been on the rise in the manufacturing industry. As companies strive to improve production efficiency and precision, the need for advanced roll forming machinery has become increasingly important. In response to this demand, [] has introduced a state-of-the-art metal roll forming machine that offers unmatched capabilities in terms of productivity and precision.The metal roll forming machine is equipped with cutting-edge technology and advanced features that are designed to streamline the production process and ensure high-quality output. With its ability to handle a wide range of metal materials such as steel, aluminum, and copper, the machine is suitable for a variety of applications in industries like automotive, construction, and aerospace.One of the key features of the metal roll forming machine is its versatile design, which allows for quick and easy tooling changes to accommodate different product specifications. This flexibility enables manufacturers to efficiently produce a diverse range of metal components and profiles with minimal downtime and setup time.In addition to its versatility, the metal roll forming machine is engineered to deliver exceptional precision and accuracy in the forming process. The machine's advanced control system and high-precision components ensure that the final products meet the required specifications with minimal variations, thus reducing the need for costly rework and ensuring customer satisfaction.Furthermore, the metal roll forming machine is equipped with advanced automation capabilities that enable continuous and uninterrupted production runs. This not only increases the overall production efficiency but also reduces labor costs and minimizes the risk of human error, resulting in significant cost savings for manufacturers.As a pioneer in the manufacturing industry, [] has a proven track record of delivering innovative solutions that empower businesses to optimize their production processes. The introduction of the metal roll forming machine is a testament to the company's commitment to providing cutting-edge technology that meets the evolving needs of the industry.The metal roll forming machine is designed and manufactured by a team of highly skilled engineers and technicians who are dedicated to ensuring the highest standard of quality and performance. This dedication to excellence is reflected in the machine's robust construction, reliable operation, and low maintenance requirements, which together contribute to its long-term durability and value.To provide comprehensive support to its customers, [] offers a range of services including machine installation, training, and technical assistance. This ensures that customers can fully leverage the capabilities of the metal roll forming machine and maximize its potential to enhance their production operations.The introduction of the metal roll forming machine underscores []'s ongoing commitment to innovation and customer satisfaction. As the manufacturing industry continues to evolve, the company remains at the forefront of providing the latest technological advancements that empower businesses to achieve greater efficiency, precision, and profitability.For more information about the metal roll forming machine and other manufacturing solutions offered by [], visit [company website] or contact [contact information].About []: [] is a leading manufacturer of advanced machinery and equipment for the manufacturing industry. With a focus on innovation, quality, and reliability, the company has established a strong reputation for delivering cutting-edge solutions that empower businesses to achieve their production goals. From metal roll forming machines to CNC systems, [] offers a comprehensive range of products and services that cater to the diverse needs of the industry. With a commitment to customer satisfaction and continuous improvement, [] is dedicated to driving positive change and progress in the manufacturing sector.

Discover the Latest Advancements in Sandwich Panel Technology for Enhanced Efficiency and Performance

Pir Sandwich Panel Becomes the Top Choice for Building ConstructionIn the modern world, building construction is evolving at a fast pace. The use of different types of building materials is on the rise, and every material is chosen based on its unique characteristics and advantages. Among all the materials available in the market, Pir Sandwich Panel is quickly rising to the top as one of the most versatile and efficient building materials used for building construction. The Pir Sandwich Panel is made up of two layers of metal sheets that are bonded to a core of polyurethane foam (PIR).The Pir Sandwich Panel is popular in the construction industry because of the many benefits that come with using this material. The panel is known for its excellent thermal insulation properties, which makes it ideal for use in cold-storage rooms, supermarkets, and various other applications. The panel is also non-combustible, which makes it an essential material for buildings that need to meet fire safety regulations. Moreover, it is a very lightweight material compared to its competitors, which makes it easier to install and transport.One of the leading companies in the industry manufacturing Pir Sandwich Panel is a company that specializes in the production of high-quality building materials. The company produces panels that are not only functional but also aesthetically pleasing. The Pir Sandwich Panel product range spans across various thicknesses and lengths that suit different construction needs, making it a versatile choice for building contractors and architects.The company's Pir Sandwich Panel has enjoyed success in various construction projects across the world. The panels have been used in building projects ranging from commercial and industrial spaces to residential apartments. The products have also been used in the construction of greenhouses, cold storage rooms, and refrigerated warehouses.The Pir Sandwich Panel from this company also boasts easy installation procedures, making it an effective option for contractors looking to complete large construction projects in a short time. The panels are available in pre-cut lengths and are easy to assemble, which saves time and labor costs. The company's Pir Sandwich Panel range has been praised by contractors for its excellent quality, versatility, and ease of installation, making it a valuable tool for businesses seeking to optimize their construction processes.Another excellent aspect of the Pir Sandwich Panel from this company is its sustainability. The company emphasizes sustainability in its production process, and the Pir Sandwich Panel is no exception. The high-quality insulation properties of the Pir Sandwich Panel lead to increased energy efficiency and savings. This feature is undoubtedly advantageous in a world where environmental sustainability is of utmost importance.In a nutshell, the Pir Sandwich Panel is an excellent building material with countless benefits. The panel's lightweight, thermal insulation, fire-resistant, and easy installation properties make it a valuable asset to contractors who want to build functional and aesthetically pleasing structures. The use of this panel ensures that buildings comply with regulatory guidelines while still delivering an energy-efficient environment for the occupants. With the continuing growth in construction demand, the Pir Sandwich Panel is an impressive addition to the list of building materials and has become the top choice for building construction. In conclusion, the myriad of benefits offered by the Pir Sandwich Panel makes it a significant advancement in the construction industry. This material is an excellent alternative to traditional building materials and boasts optimal energy efficiency. As for the company that specializes in the production of high-quality building materials, they continue to lead the industry with their expertise in the production of excellent materials for construction. By constantly upgrading their product line to meet the ever-increasing requirements of contractors and architects, the company has cemented its position at the forefront of innovation in the construction industry.

Innovative Machine for Corrugated Iron: A Game-Changer in Metal Roofing

Today, {Company Name} is proud to introduce the new Maquina Para Calaminon (need remove brand name), a state-of-the-art machine that is set to revolutionize the calaminon industry. With its cutting-edge technology and innovative features, the Maquina Para Calaminon (need remove brand name) is designed to increase productivity, enhance efficiency, and deliver high-quality results.{Company Name} has been a leading provider of industrial machinery for over 20 years, specializing in the development and production of high-performance equipment for various industries. With a strong focus on innovation and customer satisfaction, the company has built a reputation for delivering reliable and durable machines that meet the needs of its clients.The Maquina Para Calaminon (need remove brand name) is the latest addition to {Company Name}'s extensive range of products, and it is poised to set new standards in the calaminon manufacturing industry. Equipped with advanced automation technology, the machine is capable of handling the entire calaminon production process with minimal human intervention, thereby reducing labor costs and increasing efficiency.One of the key features of the Maquina Para Calaminon (need remove brand name) is its precision engineering, which ensures that each calaminon is manufactured to the highest quality standards. The machine is equipped with cutting-edge sensors and control systems that monitor and adjust the production process in real-time, thereby minimizing errors and ensuring consistent quality.In addition to its advanced automation capabilities, the Maquina Para Calaminon (need remove brand name) also boasts a user-friendly interface that makes it easy for operators to set up and monitor the machine. With intuitive controls and a touchscreen display, the machine can be easily configured to produce calaminon of various sizes and specifications, making it versatile and adaptable to different production requirements.Furthermore, the Maquina Para Calaminon (need remove brand name) is designed with sustainability in mind. It is equipped with energy-efficient components and utilizes eco-friendly materials, making it a cost-effective and environmentally friendly choice for calaminon manufacturers.{Company Name} is confident that the Maquina Para Calaminon (need remove brand name) will make a significant impact on the calaminon manufacturing industry. The machine's combination of advanced technology, precision engineering, and user-friendly design sets it apart from other machines on the market, making it an attractive investment for businesses looking to improve their production processes.To ensure that clients can make the most of the new machine, {Company Name} is also offering comprehensive training and support services to help operators maximize the potential of the Maquina Para Calaminon (need remove brand name). With expert guidance and ongoing assistance, clients can rest assured that they will be able to fully leverage the capabilities of the machine to optimize their production processes and achieve their business objectives.In conclusion, the introduction of the Maquina Para Calaminon (need remove brand name) signifies a new era in calaminon manufacturing. With its cutting-edge technology, precision engineering, and user-friendly design, the machine is set to redefine the industry standards and provide a competitive edge to businesses that invest in it. As a company committed to innovation and customer satisfaction, {Company Name} is proud to offer this groundbreaking machine to its clients, and looks forward to the positive impact it will have on the calaminon manufacturing industry.

Durable and Insulated 25mm Coolroom Panels for Commercial and Industrial Use

25mm Coolroom PanelsThe importance of maintaining a controlled temperature in various industries is undeniable. From food storage to pharmaceuticals and beyond, the need for reliable and efficient cooling solutions is crucial for numerous applications. With this in mind, a leading company in the industry, is proud to introduce their latest innovation – the 25mm Coolroom Panels.Designed to meet the highest standards of quality and performance, these panels offer unparalleled temperature control and insulation, making them an ideal choice for a wide range of applications. Featuring a thickness of 25mm, these panels are engineered to provide superior thermal efficiency, ensuring that the desired temperature is maintained consistently, regardless of external conditions.When it comes to food storage, maintaining a controlled temperature is essential to preserving the quality and safety of the products. The 25mm Coolroom Panels from are specifically designed to meet the stringent requirements of food storage facilities, ensuring that the stored items are kept at the optimal temperature to prevent spoilage and contamination.In addition to food storage, these panels are also suitable for pharmaceutical and medical storage facilities, where precise temperature control is critical to maintaining the integrity of the stored medications and vaccines. With the 25mm Coolroom Panels, companies can have peace of mind knowing that their valuable inventory is being preserved under optimal conditions.The versatility of these panels extends beyond temperature control, as they are also built to withstand the rigors of industrial environments. Whether it's a warehouse, manufacturing facility, or commercial kitchen, these panels are engineered to provide durable and reliable insulation, ensuring long-lasting performance and energy efficiency.Moreover, the installation process for these panels is straightforward, making them a cost-effective solution for businesses looking to upgrade their cooling systems. With the expertise of , companies can expect a seamless installation process, allowing them to reap the benefits of the 25mm Coolroom Panels without any disruptions to their operations.As a company committed to innovation and excellence, takes pride in offering cutting-edge cooling solutions that meet the evolving needs of various industries. With the introduction of the 25mm Coolroom Panels, continues to demonstrate its dedication to delivering high-quality products that make a positive impact on businesses and the environment.In conclusion, the 25mm Coolroom Panels from offer a compelling solution for businesses seeking reliable and efficient cooling solutions. With their superior thermal efficiency, durable construction, and easy installation, these panels are poised to make a significant difference in industries where temperature control is paramount. Whether it's food storage, pharmaceuticals, or industrial applications, companies can trust in the performance and reliability of the 25mm Coolroom Panels from .About :is a leading company specializing in cooling solutions for various industries. With a commitment to innovation and quality, has established itself as a trusted provider of high-performance cooling systems, including the recently introduced 25mm Coolroom Panels. With a focus on efficiency, reliability, and sustainability, continues to deliver solutions that meet the diverse needs of its clients while making a positive impact on the environment.

Top Options for Sheet Roofing Material

New Lightweight Roofing Material Innovates Construction IndustryRoofing plays a vital role in protecting buildings from external elements and ensuring their structural integrity. Traditionally, roofing materials have been bulky and heavy, posing several challenges during the installation process. However, a recent breakthrough in lightweight technology has revolutionized the construction industry. The new lightweight roofing material, currently in the spotlight, promises to provide efficient and sustainable roofing solutions while maintaining durability, flexibility, and cost-effectiveness.The development of this innovative roofing material aims to address the persistent issues faced by construction professionals around the world. Long gone are the days when bulky materials were necessary for adequate protection against weather conditions. Modern science has paved the way for lighter, more versatile options that provide superior performance and transform the construction landscape.Designed with efficiency in mind, this new roofing material can be easily installed, saving time and labor costs for construction companies. Its lightweight composition results in a faster installation process which in turn minimizes the disruption caused to ongoing construction projects. With fewer resources required for installation, this product is not only highly efficient but also reduces wastage, making it an eco-friendly choice for sustainable construction.The lightweight roofing material’s key strength lies in its durability. Engineered to withstand extreme weather conditions, it offers long-term protection against rain, snow, hail, and even high winds. Moreover, extensive research and rigorous testing have been conducted to ensure that this material meets and exceeds industry safety standards. Its durability is complemented by its flexibility, allowing it to adapt to various architectural designs, making it suitable for a wide range of construction projects.In addition to its functional benefits, this material offers several financial advantages to both construction companies and homeowners. The reduced installation time directly translates into lowered labor costs, ultimately leading to cost-effective solutions for construction projects. Furthermore, its lightweight nature eliminates the need for additional support structures, reducing the overall material and construction expenses. Homeowners can also benefit from long-term savings as this roofing material requires minimal maintenance and repair over its lifespan.The introduction of this roofing material has generated much excitement and anticipation within the construction industry. Several leading construction companies have already begun adopting this new innovation in their projects, recognizing its potential to transform the way buildings are constructed, while positively impacting the bottom line. Its lightweight nature and ease of installation have particularly caught the attention of architects and engineers, opening up new doors for creative and innovative designs.Moreover, the positive environmental impact of this new material cannot be overlooked. Its lightweight nature reduces transportation emissions, making it a sustainable choice. Additionally, the eco-friendly production process ensures minimal wastage and a smaller carbon footprint compared to traditional roofing materials. This aligns with the growing importance of green building practices and sustainable construction, making this new lightweight roofing material an ideal choice for environmentally-conscious individuals and organizations.As construction practices continue to evolve, lightweight roofing materials are certain to dominate the market, with potential applications spanning from residential buildings to commercial complexes. The introduction of this new roofing material marks a significant milestone in the construction industry, propelling it towards a more sustainable, efficient, and innovative future.In conclusion, the recent breakthrough in lightweight roofing materials is set to revolutionize the construction industry. The new roofing material offers an array of benefits, including easy installation, durability, flexibility, and cost-effectiveness. Its lightweight nature has caught the attention of industry professionals who are seeking solutions that align with sustainable construction practices. With these advancements, the construction industry is entering a new era, where lightweight roofing materials will become standard, transforming buildings and pushing the boundaries of architectural design.

High-Quality Roof Forming Machine for Efficient Roofing Production

Roof Forming Machine Company Advances in Innovation and EfficiencyThe roofing industry is constantly evolving, with new developments revolutionizing the way roofs are constructed. One company at the forefront of this advancement is {Company Name}. With a commitment to innovation and efficiency, {Company Name} has introduced a state-of-the-art Roof Forming Machine that is set to transform the roofing industry.{Company Name} has been a leader in the roofing industry for over 20 years, specializing in the design and production of high-quality roofing materials and machinery. The company is known for its dedication to providing innovative solutions that meet the needs of roofing professionals and homeowners alike. With a team of experienced engineers and technicians, {Company Name} has been able to develop cutting-edge roofing products and machinery that have set new standards in the industry.The latest addition to {Company Name}'s impressive lineup of roofing machinery is the Roof Forming Machine. This advanced piece of equipment is designed to streamline the process of forming and shaping roofing materials, making it easier and more efficient for roofing professionals to create high-quality roofs.The Roof Forming Machine is equipped with the latest technology, including automated controls and precision engineering, to ensure accurate and consistent results. This innovative machinery is capable of forming a wide range of roofing materials, including metal, steel, and aluminum, allowing for versatility in roofing projects. With its high-speed capabilities and customizable settings, the Roof Forming Machine is able to meet the demands of various roofing applications, from residential to commercial projects.One of the key features of the Roof Forming Machine is its efficiency. By automating the roofing forming process, {Company Name} has significantly reduced the time and labor required to create roofs, ultimately leading to cost savings for roofing professionals and their clients. This efficiency not only benefits the bottom line but also allows for quicker project completion, enabling roofing professionals to take on more work and increase their overall productivity.In addition to its efficiency, the Roof Forming Machine is also designed with user-friendliness in mind. The intuitive controls and easy-to-use interface make it accessible for roofing professionals of all skill levels, allowing them to operate the machinery with confidence and precision. This accessibility ensures that even novice users can achieve professional results, further enhancing the value of the Roof Forming Machine.With the introduction of the Roof Forming Machine, {Company Name} is once again demonstrating its commitment to driving innovation in the roofing industry. By providing roofing professionals with advanced machinery that enhances their capabilities, {Company Name} is empowering them to deliver superior roofing solutions to their clients. This commitment to excellence has solidified {Company Name} as a trusted and respected name in the roofing industry, with a track record of delivering reliable and high-quality products.As the roofing industry continues to evolve, {Company Name} remains dedicated to staying ahead of the curve. The introduction of the Roof Forming Machine is just one example of how {Company Name} is leveraging technology and innovation to provide the best possible solutions for roofing professionals. With a strong focus on research and development, {Company Name} is poised to continue leading the way in advancing the roofing industry.Overall, the introduction of the Roof Forming Machine by {Company Name} represents a significant step forward for the roofing industry. By combining efficiency, innovation, and user-friendliness, the Roof Forming Machine is set to become a game-changer for roofing professionals, providing them with the tools they need to deliver exceptional results. As {Company Name} continues to push the boundaries of what is possible in roofing technology, the future looks bright for the industry as a whole.

Efficient and Reliable Sandwich Wall Panel Production Line for Eps Panels

Eps Sandwich Wall Panel Production Line to Revolutionize Construction IndustryThe construction industry is about to witness a major revolution with the introduction of the latest Eps Sandwich Wall Panel Production Line by a leading company in the field of construction machinery. The cutting-edge technology used in this production line promises to bring about significant improvements in efficiency, cost-effectiveness, and quality in the construction of buildings.The Eps Sandwich Wall Panel Production Line is designed to produce high-quality sandwich panels that are widely used in the construction of walls, roofs, and floors. These panels are known for their excellent thermal insulation properties, lightweight, and high durability, making them a popular choice in the construction industry.The production line utilizes state-of-the-art machinery and equipment, including a highly automated process that ensures precision and consistency in the production of the panels. This not only reduces the margin of error but also increases the overall efficiency of the production process.One of the key features of the Eps Sandwich Wall Panel Production Line is its ability to produce panels of different sizes and specifications, catering to the diverse needs of the construction industry. This flexibility allows for customization and adaptation to various construction requirements, thereby expanding the possibilities for the use of these panels in different types of buildings.In addition to the superior quality of the panels, the production line is also designed to optimize the use of resources, thereby reducing waste and minimizing environmental impact. The use of advanced technology and material management systems ensures that the production process is as sustainable and eco-friendly as possible, in line with the growing demand for green building materials and practices.The introduction of this groundbreaking production line is expected to have a significant impact on the construction industry. With its ability to increase the efficiency of the production process and improve the quality of the panels, construction companies will be able to reduce costs and increase productivity. This will not only benefit the businesses themselves but also contribute to the overall growth and development of the construction industry.The new Eps Sandwich Wall Panel Production Line is a testament to the company's commitment to innovation and excellence in the field of construction machinery. With a strong focus on research and development, the company has consistently strived to introduce cutting-edge technologies that address the evolving needs of the construction industry.The company's dedication to quality and customer satisfaction has earned it a solid reputation in the market, and its products are widely recognized for their reliability and performance. The introduction of the Eps Sandwich Wall Panel Production Line is set to further strengthen the company's position as a leader in the construction machinery sector.The news of the Eps Sandwich Wall Panel Production Line has already sparked excitement and anticipation in the construction industry, with many companies eagerly awaiting the opportunity to integrate this advanced technology into their operations. The potential impact of this production line on the construction industry is significant, and it is expected to drive the industry towards greater efficiency, sustainability, and innovation in the coming years.In conclusion, the introduction of the Eps Sandwich Wall Panel Production Line is poised to revolutionize the construction industry, bringing about a new era of efficiency, quality, and sustainability. With its advanced technology and superior performance, this production line is set to make a lasting impact on the way buildings are constructed, setting new standards for the industry as a whole.

How to Build a Sheet Metal Machine for Corrugated Iron Production

[Company Introduction]Company XYZ is a leading manufacturer in the industrial machinery sector, specializing in the design, development, and production of advanced equipment for various applications. With years of experience and a dedicated team of experts, we have emerged as a trusted name in the industry, providing innovative solutions to our clients worldwide.Our company is committed to delivering high-quality, reliable, and cost-effective machinery, catering to the unique requirements of our customers. We strive to stay ahead of the curve by investing in research and development to ensure our products are at the forefront of technological advancements in the market.In line with our commitment to excellence and customer satisfaction, we are excited to introduce our latest breakthrough product, the Calaminas Manufacturing Machine. Designed to revolutionize the manufacturing process of calaminas, this state-of-the-art equipment offers numerous benefits and efficiency improvements for industrial production.[News Content]Title: Advanced Manufacturing Machine Set to Transform Calaminas Production[Location], [Date] - Company XYZ, a leading industrial machinery manufacturer, unveiled its revolutionary Calaminas Manufacturing Machine today, promising to redefine the process of producing high-quality calaminas with unprecedented efficiency and precision. This groundbreaking equipment is set to transform the construction and industrial sectors, benefiting businesses worldwide.Calaminas, also known as corrugated iron sheets, are extensively used in building roofs, walls, and other construction applications due to their durability, weather resistance, and cost-effectiveness. However, traditional calaminas manufacturing methods have often been associated with inefficiencies, high production costs, and quality inconsistencies.Addressing these challenges, Company XYZ's Calaminas Manufacturing Machine combines cutting-edge technology with years of industry expertise. The machine incorporates automated processes and advanced features, streamlining production while ensuring consistent quality and reducing costs significantly.One of the key advantages of the Calaminas Manufacturing Machine is its ability to handle a wide range of raw materials, including various grades of metal sheets and alloys. This flexibility allows manufacturers to cater to diverse client demands while maintaining optimum production levels.Furthermore, the machine's automated processes eliminate the need for manual labor, reducing the risk of human error and increasing overall productivity. The advanced control system integrated into the machine monitors and adjusts various parameters throughout the production process, ensuring precise results with minimal wastage.Another noteworthy feature of the Calaminas Manufacturing Machine is its quick setup and changeover capabilities. Manufacturers can easily switch between different calaminas designs and dimensions, reducing downtime significantly. This ensures increased production efficiency and faster turnaround times for orders, contributing to a more agile and responsive supply chain.Moreover, the machine's robust construction and durable components ensure long-term reliability and minimal maintenance requirements. It is designed to withstand the demands of continuous production operations while minimizing the potential for breakdowns and costly downtime.The introduction of Company XYZ's Calaminas Manufacturing Machine is set to drive significant improvements in the calaminas industry, benefiting manufacturers in terms of increased production efficiency, enhanced quality control, and reduced operational costs. The innovative nature of this equipment positions Company XYZ as a frontrunner in the industrial machinery sector, further strengthening its reputation as a trusted industry partner.In conclusion, the launch of Company XYZ's Calaminas Manufacturing Machine marks a significant milestone, revolutionizing the production of calaminas with its cutting-edge technology, automated processes, and enhanced efficiency. The introduction of this advanced equipment is set to reshape the calaminas industry, empowering manufacturers to meet growing market demands while maintaining a competitive edge in today's dynamic business environment.

High-Quality Eps Roll Forming Machine for Efficient Production

Eps Roll Forming Machine is revolutionizing the construction industry with its efficient and durable roll forming technology. With its state-of-the-art machinery, the company is setting new standards in the production of EPS (Expanded Polystyrene) panels and sheets for a wide range of applications.The Eps Roll Forming Machine is designed to meet the high demands of modern construction projects, delivering precise and consistent results every time. By using advanced roll forming technology, the machine is able to produce EPS panels and sheets with superior strength and durability, making them ideal for a variety of building applications.One of the key features of the Eps Roll Forming Machine is its ability to produce large quantities of EPS panels and sheets in a short amount of time, without sacrificing quality. This high level of efficiency makes it an essential tool for construction companies looking to streamline their production process and meet tight deadlines.In addition to its speed and precision, the Eps Roll Forming Machine also offers a high degree of flexibility, allowing users to create custom designs and profiles to match specific project requirements. This level of customization is invaluable for architects and builders who are looking to incorporate unique and innovative designs into their construction projects.The company behind the Eps Roll Forming Machine, {}, has a strong reputation for delivering cutting-edge solutions to the construction industry. With a history of innovation and a commitment to excellence, the company has established itself as a leader in the field of roll forming technology.With a team of highly skilled engineers and technicians, {} is dedicated to pushing the boundaries of what is possible in the world of roll forming. The company continually invests in research and development to ensure that its products remain at the forefront of technological advancements, while also providing comprehensive customer support and training to ensure that clients can make the most of their investment in a roll forming machine.In addition to its commitment to innovation, {} is also deeply committed to sustainability and environmental responsibility. The Eps Roll Forming Machine is designed to minimize waste and energy consumption, helping to reduce the environmental impact of construction projects. By using EPS panels and sheets produced by the machine, builders can contribute to a more sustainable and eco-friendly approach to construction.The Eps Roll Forming Machine has already made a significant impact on the construction industry, with numerous projects benefiting from its precision, speed, and durability. From residential buildings to commercial structures, the machine has proven its worth in a wide range of applications, demonstrating its versatility and reliability.Looking ahead, {} is committed to further advancing the capabilities of the Eps Roll Forming Machine, exploring new materials and technologies to expand its capabilities even further. The company is also continuously seeking feedback from clients and industry professionals to ensure that its products continue to meet the evolving needs of the construction industry.As the construction industry continues to evolve, the Eps Roll Forming Machine stands as a testament to the power of innovation and technological advancement. By combining cutting-edge technology with a commitment to quality and sustainability, {} is helping to shape the future of construction, one panel at a time.