Advantages of Light Gauge Steel Buildings for Construction Projects

By:Admin

The use of light gauge steel in construction offers several advantages over traditional building materials such as wood or concrete. Light gauge steel is incredibly strong and durable, making it resistant to many environmental factors such as fire, termites, and earthquakes. Additionally, it is a highly sustainable material, as it can be recycled and reused indefinitely.

In addition to these benefits, light gauge steel buildings also offer a high degree of flexibility in design and construction. With the use of computer-aided design (CAD) and manufacturing (CAM) technology, (remove brand name) is able to create custom-designed building systems that can be easily adapted to meet the specific needs of their clients. This flexibility allows for quicker and more efficient construction, saving both time and money for the project.

One of the key advantages of using light gauge steel buildings is their ability to withstand extreme weather conditions. This has been particularly important in recent years, as climate change has led to an increase in the frequency and intensity of natural disasters such as hurricanes, tornadoes, and wildfires. By using light gauge steel, (remove brand name) can provide their clients with buildings that are not only safe and durable, but also environmentally friendly.

The use of light gauge steel in construction has also been shown to have a positive impact on the environment. Unlike traditional building materials, steel is 100% recyclable, and can be reused indefinitely without losing its strength or integrity. This greatly reduces the amount of waste produced during construction, and helps to conserve natural resources.

In addition to their environmental benefits, light gauge steel buildings are also highly energy-efficient. (remove brand name) utilizes advanced insulation materials and construction techniques that help to reduce energy consumption and lower utility costs. This can be a major selling point for clients who are looking to reduce their carbon footprint and save money on long-term operating expenses.

As a leading manufacturer of light gauge steel building systems, (remove brand name) has established a strong reputation for delivering high-quality products and exceptional customer service. The company works closely with architects, engineers, and contractors to ensure that each project meets the specific needs and requirements of their clients. From the initial design phase to the final installation, (remove brand name) is committed to providing a seamless and hassle-free experience for their clients.

One of the key factors that sets (remove brand name) apart from its competitors is the company's dedication to innovation and continuous improvement. Through ongoing research and development, (remove brand name) has been able to introduce new and improved building systems that offer even greater performance and durability. This commitment to excellence has helped (remove brand name) to stay ahead of the curve in the rapidly evolving construction industry.

In conclusion, light gauge steel buildings have emerged as a highly attractive option for construction projects, thanks to their strength, durability, sustainability, and energy efficiency. As a leading manufacturer of light gauge steel building systems, (remove brand name) is well-positioned to meet the growing demand for these innovative structures. With their commitment to quality, innovation, and customer satisfaction, (remove brand name) is sure to continue making a significant impact on the construction industry for years to come.

Company News & Blog

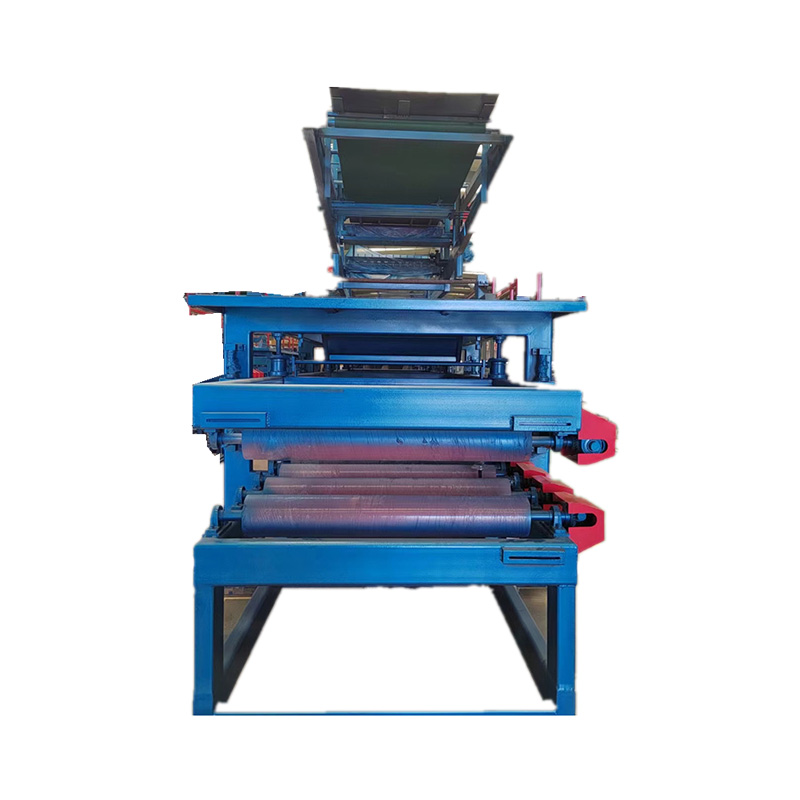

High Quality and Efficient Floor Tile Making Machine for Sale

Floor Tile Making Machine Revolutionizing the Tile Manufacturing IndustryIn recent years, the tile manufacturing industry has seen a significant transformation with the introduction of advanced machinery and technology. One such revolutionary innovation is the Floor Tile Making Machine, a state-of-the-art equipment designed to streamline the process of tile production. This groundbreaking machine has been making waves in the industry, offering a cost-effective and efficient solution to tile manufacturers.The Floor Tile Making Machine is the brainchild of a leading manufacturing company, known for its cutting-edge technology and innovative solutions. With a strong focus on research and development, the company has been at the forefront of driving innovation in the tile manufacturing sector. Their commitment to delivering high-quality and reliable machinery has earned them a stellar reputation in the industry.The Floor Tile Making Machine is a culmination of years of research and development, aimed at addressing the challenges faced by tile manufacturers. The machine is designed to automate the entire tile production process, from mixing raw materials to molding and curing the tiles. This not only reduces the reliance on manual labor but also significantly increases production efficiency.One of the key features of the Floor Tile Making Machine is its versatility. It is capable of producing a wide range of tile sizes, colors, and designs, allowing manufacturers to cater to diverse customer requirements. Additionally, the machine is equipped with advanced technology that ensures precise and consistent tile production, minimizing errors and waste.The Floor Tile Making Machine also stands out for its sustainability benefits. By optimizing the use of raw materials and reducing energy consumption, it enables manufacturers to produce tiles in an environmentally friendly manner. This aligns with the growing emphasis on sustainability within the construction and building materials industry.Furthermore, the machine is designed for ease of operation and maintenance. Its user-friendly interface and automated functions make it accessible to operators with varying levels of expertise. Additionally, the company provides comprehensive training and support to ensure that manufacturers can fully leverage the capabilities of the machine.The introduction of the Floor Tile Making Machine has been met with enthusiasm and acclaim from industry professionals. Many manufacturers have already adopted the machine in their production facilities, reaping the benefits of increased efficiency and cost savings. This has also led to a notable improvement in the quality and consistency of the tiles produced.In addition to the tangible benefits of the machine, the company behind it has also established a reputation for exceptional customer service. Their team of experts works closely with manufacturers to understand their specific needs and provide tailored solutions. This dedication to customer satisfaction has established the company as a trusted partner for tile manufacturers worldwide.Looking ahead, the Floor Tile Making Machine is poised to continue its impact on the tile manufacturing industry. As more manufacturers recognize the value of advanced machinery in improving their operations, the demand for this innovative equipment is expected to rise. With ongoing advancements and enhancements, the machine is set to redefine the standards of tile production.In conclusion, the Floor Tile Making Machine represents a significant advancement in the tile manufacturing industry, offering a high-tech and sustainable solution to streamline the production process. With its unparalleled features and the backing of a reputable manufacturing company, the machine is set to revolutionize the way tiles are made, driving efficiency, quality, and sustainability in the industry.

Advanced Hydraulic Bending Machine for Precise Metal Fabrication

Hydraulic Bending Machine Revolutionizing Manufacturing ProcessesThe manufacturing industry is constantly seeking out more efficient and precise methods to bend and shape materials to meet the demands of various industries. In recent years, the introduction of hydraulic bending machines has revolutionized the manufacturing processes, allowing for greater accuracy, speed, and versatility in bending a wide range of materials.A hydraulic bending machine utilizes hydraulic pressure to bend and shape materials such as sheet metal, pipes, and tubes. This technology has proven to be a game-changer for manufacturers, as it offers numerous advantages over traditional bending methods. With the ability to handle a variety of materials and different thicknesses, hydraulic bending machines provide unparalleled precision and flexibility in bending operations.This innovative piece of equipment has become an essential tool in the manufacturing industry, as it can produce complex bends and shapes with minimal setup and tooling changes. This not only streamlines the production process but also reduces costs and lead times, making it a highly efficient and cost-effective solution for manufacturers.One company that has been at the forefront of hydraulic bending machine technology is {}. With a legacy of innovation and a commitment to excellence, {} has continually pushed the boundaries of what is possible in the manufacturing industry. The company's hydraulic bending machines are renowned for their superior quality, reliability, and performance, making them the preferred choice for manufacturers around the world.{} offers a wide range of hydraulic bending machines to meet the diverse needs of its customers. Whether it's a small-scale operation or a large-scale production facility, {} has the expertise and technology to provide customized solutions that deliver outstanding results. From standard models to custom-built systems, {}'s hydraulic bending machines are designed to maximize efficiency and productivity while maintaining the highest standards of precision and quality.The company's dedication to research and development has enabled it to stay ahead of the curve in hydraulic bending machine technology. With a team of highly skilled engineers and technicians, {} consistently introduces new innovations and enhancements to its product lineup, ensuring that its customers have access to the latest advancements in manufacturing technology.In addition to its cutting-edge technology, {} is also committed to providing exceptional service and support to its customers. From initial consultation and installation to ongoing maintenance and technical assistance, {} goes above and beyond to ensure that its customers have a seamless and positive experience with its hydraulic bending machines.With a strong presence in the global market, {} has established itself as a trusted partner for manufacturers across a wide range of industries, including automotive, aerospace, construction, and more. Its reputation for delivering top-quality hydraulic bending machines and unparalleled customer service has earned it the trust and loyalty of its customers worldwide.As the demand for high-quality, precision-engineered products continues to grow, the role of hydraulic bending machines in the manufacturing industry will only become more significant. With their ability to streamline production processes, reduce costs, and improve overall efficiency, hydraulic bending machines are undoubtedly a game-changer for manufacturers looking to stay ahead in today's competitive market.With its unwavering commitment to excellence and innovation, {} is poised to remain at the forefront of hydraulic bending machine technology, continuously setting new standards and pushing the boundaries of what is possible in the manufacturing industry. As manufacturers continue to seek out the best solutions for their bending needs, {} will undoubtedly be the go-to partner for cutting-edge technology and exceptional value.

Latest Tr4 Maquina Described in Calaminas News

Calaminas Tr4 Maquina, the Latest Addition to a Leading Industrial Company[City], [Date] - In a bid to further bolster their position as an industry leader, [Company Name], a renowned industrial machinery manufacturer, has announced the launch of their latest product, the Calaminas Tr4 Maquina. Built with cutting-edge technology and innovative features, the Calaminas Tr4 Maquina aims to revolutionize the metal roofing industry, offering increased efficiency, durability, and versatility.With over [number of years] years of experience in producing top-quality industrial machinery, [Company Name] is constantly striving to meet the evolving needs of their diverse clientele. Driven by a commitment to innovation and customer satisfaction, the company has become synonymous with excellence in the field.The Calaminas Tr4 Maquina, built on a long-standing tradition of excellence, represents the next step in pushing boundaries and delivering advanced solutions to the metal roofing industry. Incorporating state-of-the-art technology, the machine is designed to streamline the metal roofing production process, significantly reducing production time while maintaining high-quality standards.One of the key features of the Calaminas Tr4 Maquina is its ability to handle a wide range of metal materials, ensuring versatility for various metal roofing applications. The machine's automated processes allow for precise measurements, cuts, and shaping, eliminating human error and ensuring consistency in the final product.Furthermore, the Calaminas Tr4 Maquina boasts enhanced durability with its robust construction and high-quality components. The machine's design allows for increased resistance to wear and tear, thereby minimizing downtime and maintenance costs for users. In addition, the incorporation of advanced safety features ensures a secure working environment for operators."We are thrilled to introduce the Calaminas Tr4 Maquina to the market," said [Spokesperson], the CEO of [Company Name]. "It truly represents our commitment to pushing boundaries and providing our customers with the best possible solutions. We firmly believe that this machine will revolutionize the metal roofing industry, offering unmatched efficiency and durability."With its launch, the Calaminas Tr4 Maquina is expected to make a significant impact on the metal roofing industry. Manufacturers and contractors alike can benefit from the machine's advanced capabilities, streamlining their production processes and ultimately improving their bottom line.[Company Name], with its exceptional reputation, ensures unparalleled customer support and service, assisting clients in maximizing the potential of the Calaminas Tr4 Maquina. From installation and training to ongoing support, the company remains dedicated to helping customers achieve the highest level of productivity with their latest offering.In conclusion, the launch of the Calaminas Tr4 Maquina marks a significant milestone for [Company Name]. This cutting-edge machine represents the company's dedication to innovation and customer satisfaction. With its advanced technology, versatility, and durability, the Calaminas Tr4 Maquina is set to transform the metal roofing industry, providing manufacturers and contractors with a reliable solution to meet their production needs. As [Company Name] continues to enhance its product line, their reputation as an industry leader is further solidified.

Guide to Corrugated Steel Roofing Sheet: Benefits, Installation, and Maintenance

Corrugated Steel Roofing Sheet Continues to Lead the Industry in Durability and PerformanceIn the realm of construction and infrastructure development, finding high-quality building materials is essential for ensuring the longevity and durability of structures. When it comes to roofing, the use of corrugated steel roofing sheets has become increasingly popular due to their exceptional strength, weather resistance, and long-lasting performance. Among the leading providers of corrugated steel roofing sheets in the market today is the renowned company [], which has solidified its position as a trusted supplier of top-notch building materials.Established in [], [], has consistently upheld a reputation for delivering cutting-edge products that meet the highest industry standards. With a steadfast commitment to innovation and customer satisfaction, the company has been at the forefront of revolutionizing the construction and roofing industry. Specializing in the production and distribution of corrugated steel roofing sheets, [], has continuously set the bar high for quality, reliability, and performance.Corrugated steel roofing sheets are lauded for their exceptional durability, as they are designed to withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. This makes them an ideal choice for a wide range of applications, from residential homes to industrial facilities. []One of the key advantages of using corrugated steel roofing sheets from [] is their low maintenance requirements. Unlike traditional roofing materials such as asphalt shingles or wooden shakes, corrugated steel roofing sheets are resistant to mold, rot, and insect damage. This translates to long-term cost savings for property owners, as they can enjoy a reliable roofing solution that requires minimal upkeep.Moreover, the lightweight nature of corrugated steel roofing sheets makes them easy to install, reducing labor costs and project timelines. This is particularly beneficial for contractors and builders who are seeking efficient construction solutions without sacrificing quality and performance. []In addition to their practical benefits, corrugated steel roofing sheets offered by [] are available in a variety of designs and colors, allowing for greater flexibility in architectural and design considerations. Whether a project calls for a modern, sleek appearance or a more traditional aesthetic, customers can choose from an array of options that suit their specific preferences.Furthermore, [] prides itself on its commitment to sustainability, producing corrugated steel roofing sheets that are environmentally friendly. By utilizing recyclable materials and implementing eco-conscious manufacturing processes, the company minimizes its environmental footprint while delivering eco-friendly products that contribute to sustainable building practices. This dedication to environmental responsibility aligns with the growing demand for green building materials in the construction industry.As the demand for reliable and resilient building materials continues to rise, [] is poised to remain a key player in the market, offering corrugated steel roofing sheets that stand the test of time. With a focus on quality, innovation, and customer satisfaction, the company amplifies its position as a leader in providing superior roofing solutions for a wide range of construction projects.With a proven track record of excellence and a dedication to advancing the standards of the industry, [] continues to set the benchmark for corrugated steel roofing sheets, ensuring that customers receive the best in terms of performance, durability, and value. As the construction and infrastructure sectors continue to evolve, the demand for high-quality building materials will remain paramount, and [] is well-positioned to meet and exceed these expectations.

Lightweight Steel Frames: The Ideal Choice for Construction Projects

Innovation and Sustainability: Lightweight Steel Frame Revolutionizes Construction IndustryThe construction industry has undergone a massive transformation in recent years, with many companies adopting innovative technologies to build structures that are not only efficient but sustainable. The latest addition to these innovative technologies is the lightweight steel frame, which has demonstrated its superiority in providing an optimal solution for builders in various aspects. The lightweight steel frame technology, which is a modern approach to construction, offers excellent strength, durability, and flexibility.The adoption of this groundbreaking technology has been critical in addressing some of the significant challenges commonly experienced in traditional building methods, such as long construction timelines and the weight of buildings. The lightweight steel frame construction method has revolutionized the construction industry substantially and offered numerous benefits to property owners, builders, and the environment.One company that has harnessed the power of light steel frame technology is (Company Name). The company has been at the forefront of innovative construction solutions for quite some time now. Their flagship product, the lightweight steel frame, has emerged as a popular option in the marketplace for builders who want to provide their clients with buildings of exceptional quality.The company utilizes state-of-the-art technologies, tooling and precision engineering methods to manufacture galvanized lightweight steel frames. These frames are energy-efficient, high-strength, and environmentally friendly, making them an ideal option not only for builders but property owners and the environment as well.The lightweight steel frame has been designed for use in various building projects, including commercial, residential, and industrial structures. Its suitability for such a wide range of projects has made it increasingly popular, particularly for developers looking for a construction method that promises to deliver a blend of value, quality, and sustainability.Additionally, lightweight steel frames boast of superior insulation, reducing the need for additional heating and cooling systems, and ultimately lowering the energy bills. In comparison to traditional construction methods such as brick and mortar, the steel frame’s construction takes a significantly shorter time, reducing labor costs and minimizing the chances of unexpected delays.Furthermore, the steel framing technology allows for easy customization of building plans, which optimizes flexibility throughout the construction process. The lightweight steel frame is also remarkably durable, resistant to natural elements like fire and water damage, and requires very little maintenance, thus helping building owners to save on long-term maintenance costs.One significant factor that sets (Company Name) apart is their unwavering commitment to sustainability. The company recognizes the critical role that environment conservation plays in ensuring a sustainable future and has continuously implemented measures to reduce waste, promote sustainable products, and conserve natural resources.The lightweight steel frames manufactured by (Company Name) are 100% recyclable, thus eliminating the environmental impact caused by building demolition. They are also manufactured using energy-efficient processes that significantly reduce emissions of harmful chemicals and greenhouse gases.In conclusion, the adoption of lightweight steel frames in the construction industry is a revolution that has provided a solution to some of the industry's most pressing challenges. Builders, developers, and property owners have expressed a growing preference for this technology due to their affordability, energy efficiency, sustainability, and faster construction schedules.(Company Name) is one of the companies that have successfully leveraged this innovative technology to provide their clients with exceptional buildings and contribute to sustainable development. As the world continues to grapple with environmental concerns, innovative companies like (Company Name) are a beacon of hope and a testament to the fact that in our quest for modernization, sustainability must remain at the forefront.

High-Quality Machinery for Board Making: A Comprehensive Guide

Board Making Machinery Company is a leading manufacturer of board making machinery, specializing in the design, production, installation, and maintenance of a wide range of equipment for the paperboard and paper packaging industry. With a focus on innovation, quality, and customer satisfaction, the company has established a strong reputation in the industry and continues to be a trusted partner for board making solutions.The company's product portfolio includes a variety of machinery for the production of paperboard, including corrugated cardboard, solid board, and folding carton. From the initial stages of pulp processing and board formation to the final stages of printing and converting, Board Making Machinery Company offers comprehensive solutions to meet the specific needs of its customers.In addition to its extensive range of machinery, the company also provides consulting, engineering, and technical support services to help customers optimize their production processes and achieve the highest levels of efficiency and productivity. With a team of experienced engineers and technicians, Board Making Machinery Company is able to offer customized solutions and ongoing support to ensure that its customers are able to meet their production goals and stay ahead of the competition.One of the key strengths of Board Making Machinery Company is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By constantly refining its designs and incorporating the latest advances in automation, control systems, and energy efficiency, Board Making Machinery Company is able to offer cutting-edge solutions that help its customers increase their competitiveness and sustainability.Furthermore, the company is dedicated to quality and reliability in all aspects of its operations. From the selection of high-grade materials and components to the implementation of stringent quality control processes, Board Making Machinery Company ensures that its products are built to last and perform to the highest standards. This commitment to quality has earned the company the trust and loyalty of its customers, who rely on its machinery to power their production operations day in and day out.With a global presence, Board Making Machinery Company serves customers in the paperboard and paper packaging industry around the world. Its products and services have been deployed in a wide range of applications, including the production of food and beverage packaging, consumer goods packaging, e-commerce packaging, and industrial packaging. By understanding the unique requirements of each market and application, the company is able to deliver tailored solutions that meet the specific needs of its diverse customer base.As the demand for sustainable and eco-friendly packaging solutions continues to grow, Board Making Machinery Company is also focused on developing environmentally conscious equipment and processes. The company offers solutions that minimize waste, reduce energy consumption, and maximize the use of renewable materials, helping its customers meet their sustainability goals and contribute to a greener future.In conclusion, Board Making Machinery Company is a trusted and innovative partner for board making solutions, offering a comprehensive range of machinery, technical support, and engineering services to the paperboard and paper packaging industry. With a strong commitment to quality, reliability, and sustainability, the company continues to be a leader in its field and a preferred choice for customers around the world.

Exploring the Benefits of Light Steel Frame Construction in Modern Building Practices

Light Steel Frame Construction Revolutionizing the Building IndustryLeading the way in innovative building solutions, {company name} is making waves in the construction industry with its expertise in light steel frame construction. This cutting-edge method is rapidly gaining popularity due to its numerous advantages, such as cost-effectiveness, sustainability, and versatility. By combining the strength of steel with the durability and flexibility of light materials, {company name} is revolutionizing the way buildings are constructed.Light steel frame construction involves the use of steel elements to create a structural framework for buildings. This technique offers significant advantages over traditional construction methods, primarily due to its lightweight nature. The steel frames are prefabricated off-site, allowing for efficient assembly on-site, reducing construction time and costs significantly.One of the major benefits of light steel frame construction is its eco-friendliness. Using this construction method significantly reduces the carbon footprint, as steel is a fully recyclable material. Additionally, the production of steel generates minimal waste compared to traditional building materials, such as concrete and wood. By adopting light steel frame construction, {company name} is contributing to a more sustainable future by reducing construction waste and minimizing the impact on the environment.Furthermore, light steel frame construction offers exceptional durability. Steel is highly resistant to external forces, such as wind, earthquakes, and even fire. By utilizing steel frames, buildings constructed by {company name} are better equipped to withstand natural disasters and maintain structural integrity over a longer period. This translates to reduced maintenance costs and increased safety for occupants.In addition to its durability, light steel frame construction provides unparalleled design flexibility. The lightweight nature of the steel frames allows for greater freedom in architectural design. {company name} prides itself on its ability to deliver customized, aesthetically pleasing structures that meet the specific requirements of its clients. Whether it's residential, commercial, or industrial buildings, {company name} seamlessly blends functionality and design to create stunning and practical spaces.Moreover, light steel frame construction has proven to be cost-effective. Due to the prefabrication process, construction time is significantly reduced, resulting in lower labor costs and quicker project completion. Additionally, the durability of steel eliminates the need for regular maintenance and repair, saving clients money in the long run. By implementing light steel frame construction, {company name} enables clients to maximize cost efficiency without compromising on quality.As a leader in the field, {company name} has successfully completed numerous projects utilizing light steel frame construction techniques. From residential homes to multi-story buildings, their portfolio demonstrates the versatility and excellence of their work. The company prides itself on delivering projects on time and within budget, providing exceptional service to clients across various sectors.Harnessing the power of innovation, {company name} continually invests in research and development to enhance their light steel frame construction methods. By staying at the forefront of technological advancements and industry trends, they ensure that their projects meet the highest standards of quality, safety, and sustainability.In conclusion, light steel frame construction is revolutionizing the building industry, and {company name} is leading the way in this innovative approach. With its numerous benefits, including cost-effectiveness, sustainability, durability, and design flexibility, this construction method is rapidly gaining popularity. Through their expertise and experience, {company name} is reshaping the landscape of construction, delivering buildings that are both practical and aesthetically pleasing. As they continue to push the boundaries of what is possible, {company name} is setting new standards for excellence in the industry and paving the way for a more sustainable and efficient future.

High-Quality Roofing Tile Making Machine for Efficient Production

Roofing Tile Making Machine: Revolutionizing the Roofing IndustryThe roofing industry is about to witness a significant transformation with the introduction of the state-of-the-art Roofing Tile Making Machine by {Company Name}. This innovative machine is set to revolutionize the way roofing tiles are manufactured, offering a more efficient and cost-effective solution for roofing contractors and manufacturers.With a growing demand for durable and aesthetically pleasing roofing tiles, the need for advanced manufacturing equipment has become more apparent. The Roofing Tile Making Machine not only meets this demand but also sets a new standard for quality and efficiency in the industry.{Company Name}, the manufacturer behind this groundbreaking machine, has been a leading player in the construction and manufacturing sector for over two decades. Their commitment to innovation and excellence has earned them a reputation for delivering cutting-edge solutions that meet the evolving needs of their customers.The Roofing Tile Making Machine is a testament to the company's dedication to providing state-of-the-art equipment for the construction industry. This machine is designed to streamline the production process, allowing for faster and more precise manufacturing of roofing tiles. It is equipped with advanced technology that ensures the consistent quality of the tiles, making them highly durable and long-lasting.One of the key features of the Roofing Tile Making Machine is its versatility. It can produce a wide range of roofing tiles, including clay, concrete, and slate tiles, catering to the diverse needs of roofing contractors and manufacturers. This flexibility sets the machine apart from traditional methods of tile manufacturing, which often require separate equipment for each type of tile.Moreover, the Roofing Tile Making Machine is designed with efficiency in mind. It is equipped with automated systems that minimize human intervention, reducing the risk of errors and increasing production output. This not only saves time but also significantly lowers manufacturing costs, making it an attractive investment for businesses in the roofing industry.In addition to its efficiency, the machine is also designed for ease of operation and maintenance. Its user-friendly interface and intuitive controls make it accessible to operators with minimal training, while its robust construction ensures long-term reliability and minimal downtime.The introduction of the Roofing Tile Making Machine is expected to have a significant impact on the roofing industry. With its advanced capabilities and cost-effective benefits, it is poised to become the go-to solution for roofing tile manufacturing, setting new standards for quality and efficiency.{Company Name} is committed to supporting its customers in adopting this new technology, offering comprehensive training and support services to ensure a smooth transition to the Roofing Tile Making Machine. With their extensive experience and expertise in the construction industry, they are well-positioned to provide the necessary guidance and assistance for businesses looking to integrate this innovation into their operations.As the roofing industry continues to evolve, the Roofing Tile Making Machine represents a major advancement that will shape the future of roofing tile manufacturing. Its impact is expected to be felt across the industry, driving greater efficiency, higher quality, and ultimately, more satisfied customers.In conclusion, the Roofing Tile Making Machine by {Company Name} is a game-changing innovation that is set to redefine the way roofing tiles are manufactured. With its advanced technology, versatility, efficiency, and user-friendly design, it is poised to become an indispensable asset for businesses in the roofing industry. This revolutionary machine is a testament to {Company Name}'s commitment to delivering cutting-edge solutions that meet the evolving needs of the construction industry.

Exploring the Benefits of Color Coated Steel Coils for Various Applications

Color Coated Steel Coil Production Gets the Boost with Advanced TechnologyColor coated steel coils have been the go-to material for building construction and various other industries. With the advancements in technology, the production of color coated steel coils has become more efficient, cost-effective, and eco-friendly. One such company that has been leading the way in the production of quality color coated steel coils is a China-based firm that has been working hard towards bringing innovative solutions to the market.Over the years, the company has honed its production processes, making them more sustainable and efficient. They have implemented advanced production equipment, state-of-the-art technology, and eco-friendly operations that have given them an edge in the market. The combination of all these factors has helped the company achieve a reputation for producing high-quality color-coated steel coils that are optimized for a variety of applications.One of the latest innovations that the company has introduced is the high-speed color coating line that has been designed to improve production output and efficiency. The line is equipped with advanced sensors and control systems that ensure that the color-coating process is uniform and consistent across the entire length of the steel coil. This minimizes the amount of raw material wastage, reduces the production time, and improves the quality of the final product.Another important improvement that the company has made to its production processes is the implementation of a solvent recovery system. The system is designed to reduce the emission of volatile organic compounds (VOCs) that are hazardous to the environment. The VOCs are captured and reused in the production process, reducing the company’s carbon footprint and contributing to a cleaner, more sustainable environment.The company’s commitment to quality is evident in the fact that they source raw materials from only the most reliable suppliers. The raw materials are carefully inspected and tested to meet the company’s strict quality standards. This ensures that the final product is of the highest quality and meets international standards.Apart from the quality of its products, the company is also known for its excellent customer service. Their team of professionals guide customers through the entire production process, from selecting the right grade of steel to final delivery. They work closely with customers to ensure that their requirements are met and that all specifications are adhered to.The company’s color-coated steel coils are ideal for a range of applications including roofing, cladding, and construction. The coils are available in a range of colors, thicknesses, and widths, giving customers the flexibility to choose the perfect product for their needs. The company’s color-coated steel coils are also highly durable, weather-resistant, and have excellent corrosion resistance, making them ideal for use in harsh environments.The company is committed to providing quality products that are optimized for performance and sustainability. They have invested heavily in research and development, product innovation, and production efficiency, making them a market leader in the color-coated steel coil sector. The company’s commitment to customer satisfaction is unwavering, and they strive to deliver products that exceed customer expectations.In conclusion, the company has set a benchmark in the color-coated steel coil market with a commitment to quality, sustainability, and innovation. With an unwavering focus on customer satisfaction and a relentless drive to improve its product offerings, the company is well-positioned to continue dominating the market for years to come.

High-Quality Metal Roll Forming Machine for Efficient Production

Metal Roll Forming Machine Revolutionizes Manufacturing IndustryWith the continuous development of the manufacturing industry, the demand for efficient and high-quality equipment is ever increasing. In response to this need, {company} has introduced a revolutionary metal roll forming machine that is set to transform the way metal products are manufactured.The metal roll forming machine, designed and developed by {company}, is a state-of-the-art piece of equipment that is capable of seamlessly shaping metal sheets into various profiles and designs. This innovative machine is equipped with advanced technology and features a precision control system that allows for the production of high-quality and accurate metal products.One of the key advantages of {company}'s metal roll forming machine is its versatility. It has the ability to produce a wide range of metal products, including roofing panels, wall cladding, steel framing, and various other components used in the construction and manufacturing industry. This versatility makes it an invaluable asset for companies involved in metal fabrication and manufacturing.In addition to its versatility, the metal roll forming machine boasts impressive speed and efficiency. It is capable of producing large volumes of metal products in a relatively short amount of time, without compromising on quality. This makes it an ideal solution for companies looking to streamline their manufacturing processes and improve their overall productivity.Furthermore, {company}'s metal roll forming machine is designed with user convenience in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and maintain. This ensures that operators can quickly adapt to using the machine and maximize its performance from the get-go.The introduction of this cutting-edge metal roll forming machine marks a significant milestone for {company}, as it further solidifies their position as a leader in the manufacturing equipment industry. Leveraging their expertise and industry knowledge, {company} has successfully developed a machine that addresses the evolving needs of the manufacturing sector.The metal roll forming machine is a testament to {company}'s commitment to innovation and continuous improvement. By investing in research and development, {company} has been able to create a product that not only meets the current demands of the market but also sets new standards for efficiency and quality in metal manufacturing.As the manufacturing industry continues to evolve, the introduction of {company}'s metal roll forming machine is set to have a profound impact on how metal products are produced. Its versatility, speed, and user-friendly design make it a valuable asset for companies looking to stay ahead in a competitive market.Looking ahead, {company} remains dedicated to pushing the boundaries of innovation and delivering solutions that empower manufacturers to achieve their production goals. With the metal roll forming machine, {company} is taking manufacturing to new heights, revolutionizing the industry and setting a new standard for excellence.