Guide to Roll Forming Aluminum: Benefits, Process, and Applications

By:Admin

The roll forming process is a highly versatile method of shaping aluminum into a variety of profiles and cross-sections. By passing a continuous strip of aluminum through a series of rollers, [Company Name] is able to produce complex and precise shapes with minimal waste and excellent dimensional consistency. This makes roll forming an ideal manufacturing technique for industries such as construction, automotive, aerospace, and more.

One of the key advantages of roll forming aluminum is its ability to produce long lengths and large quantities of parts with minimal lead times. This means that [Company Name] is able to provide its customers with cost-effective solutions for high-volume production runs, while maintaining the highest standards of quality and precision.

In addition to its expertise in roll forming aluminum, [Company Name] also offers a wide range of finishing and fabrication services to meet the unique needs of its customers. Whether it's powder coating, anodizing, or custom punching and bending, [Company Name] has the capabilities to deliver a fully finished product that meets the most demanding specifications.

One recent example of [Company Name]'s success in roll forming aluminum can be seen in its collaboration with a major automotive manufacturer. By working closely with the customer's engineering team, [Company Name] was able to develop a complex aluminum profile that met the stringent requirements for weight, strength, and durability. The result was a high-performance component that contributed to the overall success of the customer's vehicle.

Another area in which [Company Name] excels is in providing sustainable solutions for its customers. By using recycled aluminum and minimizing waste in the roll forming process, [Company Name] is able to support its customers' sustainability goals while delivering exceptional products that meet the highest standards of quality and performance.

Looking ahead, [Company Name] is committed to continuous innovation and investment in its roll forming capabilities. By staying at the forefront of technology and industry trends, [Company Name] is well positioned to meet the evolving needs of its customers and provide them with the most advanced and cost-effective solutions for their aluminum forming needs.

In conclusion, [Company Name] is a recognized leader in the roll forming aluminum industry, with a proven track record of delivering high-quality, customized solutions for a wide range of industries. With its expertise, commitment to innovation, and focus on sustainability, [Company Name] is a trusted partner for businesses seeking efficient and cost-effective aluminum forming solutions.

Company News & Blog

New Roll Forming Machine Revolutionizes Light Keel Production

Title: Innovative Light Keel Roll Forming Machine: Revolutionizing Construction EfficiencyIntroduction:In the continuously evolving construction industry, the demand for advanced and efficient machinery is paramount. Addressing this need, a leading manufacturing company has unveiled the Tbar Tgrid Light Keel Roll Forming Machine, a groundbreaking solution that promises to revolutionize the construction sector.The Tbar Tgrid Light Keel Roll Forming Machine is designed to streamline the process of manufacturing light keel frames for various applications such as suspended ceilings, partition walls, and steel floor joists. Equipped with cutting-edge technology, this advanced machinery offers a plethora of features that enhance productivity, accuracy, and efficiency.1. Enhanced Productivity:The Tbar Tgrid Light Keel Roll Forming Machine enables construction companies to significantly improve their productivity levels. By automating the process of manufacturing light keel frames, it eliminates the need for manual labor, thereby reducing human error and saving valuable time. This state-of-the-art machine can produce a high volume of standardized light keel frames within a short period, meeting the demands of large-scale construction projects.2. Precision Engineering:Precision plays a vital role in the construction industry, especially when it comes to assembling structural components. The Tbar Tgrid Light Keel Roll Forming Machine incorporates cutting-edge technology, guaranteeing precise measurements and accurate cutting of light keel frames. The machine's advanced control system ensures uniformity and consistency in producing high-quality light keel frames, minimizing waste and improving overall project efficiency.3. Versatile Applications:One of the notable advantages of the Tbar Tgrid Light Keel Roll Forming Machine is its versatility in producing a wide range of light keel frames. Whether it is suspended ceilings, partition walls, or steel floor joists, this revolutionary machine can manufacture various light keel profiles with ease. This flexibility allows construction companies to adapt to different projects' requirements seamlessly, maximizing the utilization of this innovative machinery.4. Cost-Effectiveness:The Tbar Tgrid Light Keel Roll Forming Machine's efficiency extends beyond productivity and precision; it offers a cost-effective solution for construction companies. By automating the manufacturing process, labor costs are minimized, while the consistent production of high-quality frames reduces material waste and related expenses. With long-term savings in operating costs, the machine offers an excellent return on investment for construction businesses.5. User-Friendly Design:Designed with usability in mind, the Tbar Tgrid Light Keel Roll Forming Machine is easy to operate, even for those with minimal technical experience. The intuitive interface provides clear instructions for setup, production control, and maintenance, ensuring minimal downtime and optimal efficiency. Organizations can quickly train their workforce to operate the machine, allowing for seamless integration into their manufacturing processes.Conclusion:With the introduction of the Tbar Tgrid Light Keel Roll Forming Machine, the construction industry has witnessed a significant advancement in manufacturing capabilities. Its cutting-edge features, including enhanced productivity, precision engineering, versatile applications, cost-effectiveness, and user-friendly design, make it an indispensable asset for construction companies globally. This innovative machinery marks a paradigm shift in construction efficiency, offering immense potential to revolutionize the way light keel frames are manufactured, ultimately improving the overall quality, speed, and cost-effectiveness of construction projects.

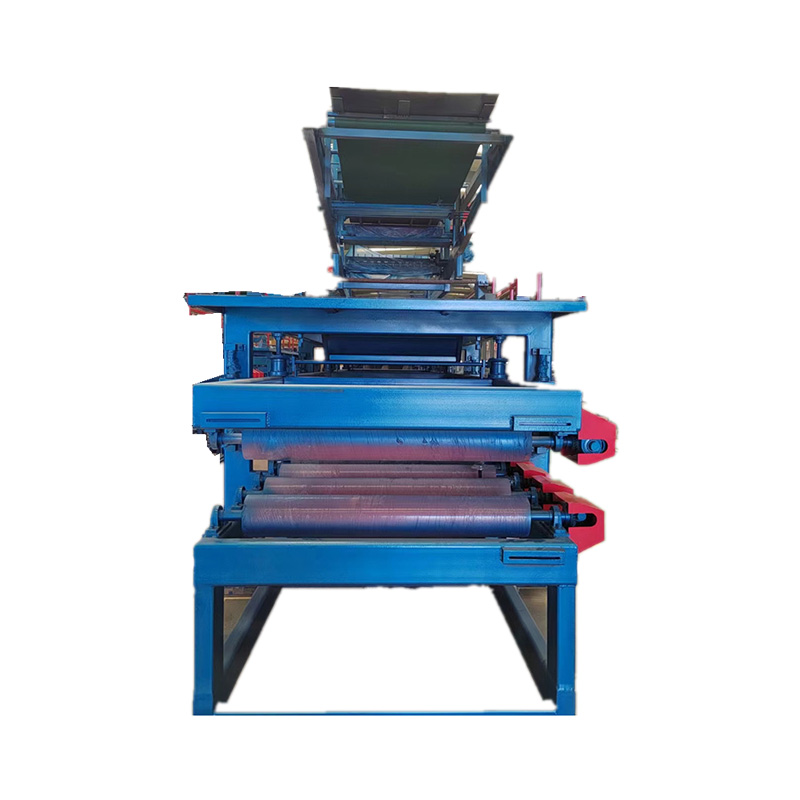

High-quality Corrugated Roll Forming Machine for Efficient Production

[Company Name] introduces advanced corrugated roll forming machine[City, Date] – [Company Name], a leading manufacturer of roll forming equipment, has recently launched an advanced corrugated roll forming machine that is set to revolutionize the industry. The new machine is designed to increase productivity, reduce material waste, and improve the overall quality of corrugated products.The [Company Name] corrugated roll forming machine is equipped with the latest technology and features a high-speed roller and precision control system that ensures consistent and accurate production. The machine also boasts a user-friendly interface, making it easy to operate and maintain.With the introduction of this new machine, [Company Name] aims to provide its customers with a solution that addresses the challenges faced in the corrugated industry. The machine is capable of producing a wide range of corrugated products, including roofing panels, wall cladding, and decking, with exceptional speed and efficiency.The [Company Name] corrugated roll forming machine is also designed to minimize material waste, thanks to its precise cutting and forming capabilities. This not only helps to reduce production cost but also contributes to environmental sustainability.In addition to its cutting-edge technology, the [Company Name] corrugated roll forming machine is backed by the company’s commitment to customer support and service. The company’s team of experienced engineers and technicians are available to provide training, technical assistance, and maintenance services, ensuring that customers get the most out of their investment.[Company Name] has a long-standing reputation for delivering high-quality and reliable roll forming equipment. The company’s commitment to innovation and customer satisfaction has made it a trusted partner for businesses in the metal forming industry.“We are excited to introduce our new corrugated roll forming machine to the market,” said [Spokesperson Name], [Position at Company]. “We believe that this machine will set a new standard for productivity, quality, and efficiency in the corrugated industry. Our team has put a lot of effort into developing this machine, and we are confident that it will meet the needs of our customers and help them stay ahead in a competitive market.”The introduction of the new corrugated roll forming machine is a testament to [Company Name]’s commitment to delivering innovative solutions that drive customer success. The company’s dedication to research and development, combined with its team of experts, ensures that it continues to lead the way in the roll forming industry.With its advanced technology, precision engineering, and exceptional customer support, the [Company Name] corrugated roll forming machine is set to make a significant impact on the industry. Businesses in the corrugated industry can now look forward to increased productivity, improved quality, and reduced material waste, thanks to this groundbreaking machine from [Company Name]. For more information about the [Company Name] corrugated roll forming machine, or to schedule a demonstration, please visit [company website] or contact [company contact information].About [Company Name]:[Company Name] is a leading manufacturer of roll forming equipment, specializing in providing innovative solutions for the metal forming industry. With a focus on quality, reliability, and customer satisfaction, the company has earned a reputation as a trusted partner for businesses looking to enhance their manufacturing processes. [Company Name] is committed to delivering cutting-edge technology and exceptional service to help its customers stay ahead in a competitive market.

Heavy-Duty Machine for Corrugated Metal Sheets - A must-have for roofing and construction projects

CHAPTER 1Introduction of the CompanyFounded in 1982, our company has been dedicated to providing high-quality machinery and equipment to industries around the world. We have continuously strived to innovate and improve our products to meet the demands of our customers. Our commitment to excellence has made us a leader in the manufacturing industry, and we take pride in offering top-of-the-line solutions to our clients. Our machines are known for their durability, efficiency, and advanced technology, making them the perfect choice for businesses looking to streamline their operations and increase productivity.CHAPTER 2Maquina Para Calaminon: A New Addition to Our Product LineWe are proud to announce the latest addition to our extensive line of machinery: the Maquina Para Calaminon (need remove brand name). This cutting-edge machine is designed to revolutionize the process of producing calaminon, a popular building material used in a wide range of construction projects. Developed with advanced technology and engineered for optimal performance, the Maquina Para Calaminon is set to become an essential tool for businesses in the construction industry.CHAPTER 3Features and Benefits of the Maquina Para CalaminonThe Maquina Para Calaminon offers a range of features that sets it apart from other machines on the market. Its state-of-the-art design allows for precision manufacturing of calaminon, ensuring uniformity and consistency in every piece produced. The machine is equipped with a high-speed cutting system, which results in increased productivity and reduced downtime. Additionally, the Maquina Para Calaminon is designed to be user-friendly and easily adjustable, making it suitable for businesses of all sizes.The benefits of the Maquina Para Calaminon are numerous. By incorporating this machine into their operations, businesses can expect to see improvements in efficiency, cost savings, and overall product quality. The machine's advanced technology and precision engineering make it a valuable asset for any company looking to stay ahead of the competition and meet the demands of today's construction industry.CHAPTER 4Customer TestimonialsSeveral businesses have already integrated the Maquina Para Calaminon into their operations and have reported outstanding results. One customer, a large construction company, stated that the machine has significantly improved their production process, allowing them to meet tight deadlines and fulfill large orders with ease. Another customer, a small manufacturing firm, praised the user-friendly design of the Maquina Para Calaminon, noting that it has made a significant impact on their bottom line.CHAPTER 5ConclusionThe Maquina Para Calaminon represents a new era in the manufacturing industry. With its advanced technology, precision engineering, and user-friendly design, it is set to become an essential tool for businesses in the construction industry. By choosing the Maquina Para Calaminon, companies can expect to see improvements in efficiency, cost savings, and overall product quality. We are excited to introduce this innovative machine to the market and look forward to continuing to provide top-of-the-line solutions to our clients.

High-Quality Roll Forming Machine for Efficient Production

Roll Forming Machine Revolutionizing the Metalworking IndustryThe metalworking industry is no stranger to technological advancements and innovative machinery. The introduction of roll forming machines has been a game changer for companies involved in metal fabrication and manufacturing. These machines have transformed the way metal sheets and coils are processed and shaped, providing greater precision, efficiency, and cost-effectiveness.{Company name} is at the forefront of this technological revolution, specializing in the design and manufacturing of cutting-edge roll forming machines. With a rich history of innovation and excellence, {company name} has established itself as a leader in the industry, delivering state-of-the-art solutions to meet the evolving needs of metalworking businesses.The roll forming machine developed by {company name} is a versatile and high-performance piece of equipment that is designed to handle a wide range of metal materials, including steel, aluminum, copper, and more. This flexibility makes it a valuable asset for companies working with diverse materials and seeking to streamline their production processes. The machine can efficiently produce various profiles and shapes, from simple bends to complex geometries, making it a valuable tool for a wide range of applications.One of the key features that set {company name}'s roll forming machine apart is its advanced automation and control systems. These features allow for precise and repeatable forming processes, minimizing material waste and ensuring consistent quality in the final products. Additionally, the machine is equipped with intelligent monitoring and diagnostic tools, enabling operators to optimize performance and troubleshoot potential issues in real time. This level of automation not only increases efficiency but also reduces the need for extensive manual labor, contributing to a safer and more productive work environment.In addition to its cutting-edge technology, {company name}'s roll forming machine is designed with user-friendly interfaces and intuitive controls, making it accessible to operators of varying skill levels. This ensures that companies can quickly integrate the machine into their existing workflows and begin reaping the benefits of its capabilities without a steep learning curve. Whether it's creating custom profiles or mass-producing standardized components, the machine offers the flexibility and ease of use that modern metalworking businesses demand.Moreover, {company name} takes pride in its commitment to sustainability and energy efficiency. The roll forming machine is engineered to minimize energy consumption and reduce environmental impact, aligning with the industry's growing focus on sustainable practices. By investing in a machine that prioritizes eco-friendly operation, businesses can not only contribute to a greener future but also potentially reduce their operating costs over the long term.As the metalworking industry continues to evolve and adapt to changing market demands, the role of advanced machinery such as {company name}'s roll forming machine becomes increasingly significant. It offers a competitive edge to companies seeking to stay ahead of the curve and meet the complex requirements of their customers. With its precision, efficiency, and versatility, the machine has the potential to revolutionize the way metal products are manufactured, setting new standards for quality and performance.In conclusion, {company name}'s roll forming machine represents a major advancement in the field of metalworking, empowering businesses with the tools they need to thrive in a highly competitive market. Its combination of cutting-edge technology, user-friendly design, and sustainability features positions it as a valuable asset for companies looking to elevate their production capabilities. As the industry continues to embrace innovation, {company name} remains a trusted partner for those seeking top-of-the-line roll forming solutions.

High-Quality Glazed Tile Roll Forming Machine for Efficient Production

article:Glazed tile roll forming machines are an essential piece of technology in modern construction, enabling the production of coated, high-quality tiles that add a touch of elegance to any building project. They represent significant investments for companies involved in the roofing and construction industry, and investing in the right machine means maximizing efficiency while reducing production costs. In response to this need, the engineers at a leading company (need to remove brand name) have developed their latest product, the 960 Glazed Tile Roll Forming Machine. This machine is designed to meet the specialized needs of roofing manufacturers who want to produce glazed tiles with a beautiful, smooth finish. The 960 Glazed Tile Roll Forming Machine is constructed with the highest standards of quality and performance. Its body is made of precision-machined metal and its main components are made of durable materials that ensure longevity, reliability and efficiency. This machine also has the latest computer controls that allow operators to produce tiles with the exact specifications required by their clients. With this machine, roofing manufacturers can increase their production rates and improve their overall efficiency, ultimately saving significant amounts of time and money.The machine is easy to use and doesn't require complex training. It has been designed with user-friendliness in mind, which means it can be operated by any skilled worker with ease. Demands for fast and seamless production can be met with its powerful and efficient mechanism, which guarantees high performance and a large production output. The 960 Glazed Tile Roll Forming Machine has a simple structure and a compact design. This makes it easy to transport and install, even in locations with limited space. It can also be customized according to specific requirements to meet the particular needs of customers. This flexibility allows roofing manufacturers to produce a variety of coated tiles with different specifications, giving them a competitive edge in the market.One major advantage of the 960 Glazed Tile Roll Forming Machine is its low energy and maintenance costs. As it has been designed to run with precision, it has lower energy consumption rates and produces less wastage, which translates to an increase in the overall cost-effectiveness of production. Further, this machine has been designed with minimal maintenance requirements to ensure it operates with optimal performance over a long period of time.In summary, the 960 Glazed Tile Roll Forming Machine is a state-of-the-art piece of equipment that can help roofing manufacturers to produce high-quality glazed tiles with ease. The machine's precision, ease of use, and flexibility make it a valuable asset in the construction industry. As the need for modern roofing materials grows, this machine is poised to play an increasingly important role in transforming the industry.The engineering and design team behind this revolutionary product is dedicated to providing continuous innovation to help roofing manufacturers stay ahead of the competition. With the 960 Glazed Tile Roll Forming Machine, roofing manufacturers can produce glazed tiles efficiently and at lower costs, leading to more significant revenue growth. The company is committed to delivering exceptional customer service and support to ensure their customers can make the most of their investments in this machine. Overall, roofing manufacturers who invest in the 960 Glazed Tile Roll Forming Machine will reap the benefits of increased efficiency, higher production rates, and reduced production costs. The machine's advanced features and the company's exceptional customer care make it a highly valuable investment that will add value to any construction project. As the market for coated tiles continues to grow, the 960 Glazed Tile Roll Forming Machine is a worthy addition to any roofing manufacturer's facility.

Guide to Roll Forming Aluminum: Benefits, Process, and Applications

[Company Name] is a leading manufacturer of roll forming aluminum products, specializing in providing high-quality, customized solutions for a wide range of industries. With a commitment to innovation and excellence, [Company Name] has become a trusted partner for businesses seeking efficient and cost-effective aluminum forming solutions.The roll forming process is a highly versatile method of shaping aluminum into a variety of profiles and cross-sections. By passing a continuous strip of aluminum through a series of rollers, [Company Name] is able to produce complex and precise shapes with minimal waste and excellent dimensional consistency. This makes roll forming an ideal manufacturing technique for industries such as construction, automotive, aerospace, and more.One of the key advantages of roll forming aluminum is its ability to produce long lengths and large quantities of parts with minimal lead times. This means that [Company Name] is able to provide its customers with cost-effective solutions for high-volume production runs, while maintaining the highest standards of quality and precision.In addition to its expertise in roll forming aluminum, [Company Name] also offers a wide range of finishing and fabrication services to meet the unique needs of its customers. Whether it's powder coating, anodizing, or custom punching and bending, [Company Name] has the capabilities to deliver a fully finished product that meets the most demanding specifications.One recent example of [Company Name]'s success in roll forming aluminum can be seen in its collaboration with a major automotive manufacturer. By working closely with the customer's engineering team, [Company Name] was able to develop a complex aluminum profile that met the stringent requirements for weight, strength, and durability. The result was a high-performance component that contributed to the overall success of the customer's vehicle.Another area in which [Company Name] excels is in providing sustainable solutions for its customers. By using recycled aluminum and minimizing waste in the roll forming process, [Company Name] is able to support its customers' sustainability goals while delivering exceptional products that meet the highest standards of quality and performance.Looking ahead, [Company Name] is committed to continuous innovation and investment in its roll forming capabilities. By staying at the forefront of technology and industry trends, [Company Name] is well positioned to meet the evolving needs of its customers and provide them with the most advanced and cost-effective solutions for their aluminum forming needs.In conclusion, [Company Name] is a recognized leader in the roll forming aluminum industry, with a proven track record of delivering high-quality, customized solutions for a wide range of industries. With its expertise, commitment to innovation, and focus on sustainability, [Company Name] is a trusted partner for businesses seeking efficient and cost-effective aluminum forming solutions.

How to Build a Sheet Metal Machine for Corrugated Iron Production

[Company Introduction]Company XYZ is a leading manufacturer in the industrial machinery sector, specializing in the design, development, and production of advanced equipment for various applications. With years of experience and a dedicated team of experts, we have emerged as a trusted name in the industry, providing innovative solutions to our clients worldwide.Our company is committed to delivering high-quality, reliable, and cost-effective machinery, catering to the unique requirements of our customers. We strive to stay ahead of the curve by investing in research and development to ensure our products are at the forefront of technological advancements in the market.In line with our commitment to excellence and customer satisfaction, we are excited to introduce our latest breakthrough product, the Calaminas Manufacturing Machine. Designed to revolutionize the manufacturing process of calaminas, this state-of-the-art equipment offers numerous benefits and efficiency improvements for industrial production.[News Content]Title: Advanced Manufacturing Machine Set to Transform Calaminas Production[Location], [Date] - Company XYZ, a leading industrial machinery manufacturer, unveiled its revolutionary Calaminas Manufacturing Machine today, promising to redefine the process of producing high-quality calaminas with unprecedented efficiency and precision. This groundbreaking equipment is set to transform the construction and industrial sectors, benefiting businesses worldwide.Calaminas, also known as corrugated iron sheets, are extensively used in building roofs, walls, and other construction applications due to their durability, weather resistance, and cost-effectiveness. However, traditional calaminas manufacturing methods have often been associated with inefficiencies, high production costs, and quality inconsistencies.Addressing these challenges, Company XYZ's Calaminas Manufacturing Machine combines cutting-edge technology with years of industry expertise. The machine incorporates automated processes and advanced features, streamlining production while ensuring consistent quality and reducing costs significantly.One of the key advantages of the Calaminas Manufacturing Machine is its ability to handle a wide range of raw materials, including various grades of metal sheets and alloys. This flexibility allows manufacturers to cater to diverse client demands while maintaining optimum production levels.Furthermore, the machine's automated processes eliminate the need for manual labor, reducing the risk of human error and increasing overall productivity. The advanced control system integrated into the machine monitors and adjusts various parameters throughout the production process, ensuring precise results with minimal wastage.Another noteworthy feature of the Calaminas Manufacturing Machine is its quick setup and changeover capabilities. Manufacturers can easily switch between different calaminas designs and dimensions, reducing downtime significantly. This ensures increased production efficiency and faster turnaround times for orders, contributing to a more agile and responsive supply chain.Moreover, the machine's robust construction and durable components ensure long-term reliability and minimal maintenance requirements. It is designed to withstand the demands of continuous production operations while minimizing the potential for breakdowns and costly downtime.The introduction of Company XYZ's Calaminas Manufacturing Machine is set to drive significant improvements in the calaminas industry, benefiting manufacturers in terms of increased production efficiency, enhanced quality control, and reduced operational costs. The innovative nature of this equipment positions Company XYZ as a frontrunner in the industrial machinery sector, further strengthening its reputation as a trusted industry partner.In conclusion, the launch of Company XYZ's Calaminas Manufacturing Machine marks a significant milestone, revolutionizing the production of calaminas with its cutting-edge technology, automated processes, and enhanced efficiency. The introduction of this advanced equipment is set to reshape the calaminas industry, empowering manufacturers to meet growing market demands while maintaining a competitive edge in today's dynamic business environment.

High-quality Metal Roof Tile Making Machine for Sale

Introducing a Revolutionary Stone Coated Metal Roof Tile Making MachineThe manufacturing industry is constantly evolving, with new technologies and innovations driving the market forward. One such innovation that has been making waves in the industry is the Stone Coated Metal Roof Tile Making Machine developed by a leading machinery manufacturer. This cutting-edge machine has been designed to revolutionize the production process of stone-coated metal roof tiles, offering a more efficient and cost-effective solution for manufacturers.The Stone Coated Metal Roof Tile Making Machine is a state-of-the-art piece of equipment that has been engineered to streamline the production of high-quality roof tiles. It is capable of producing a wide range of tile designs and sizes, allowing manufacturers to meet the diverse needs of their customers. The machine is also highly versatile, accommodating various materials and thicknesses, giving manufacturers the flexibility to adapt to different project requirements.One of the key features of the Stone Coated Metal Roof Tile Making Machine is its advanced automation technology. This allows for precise and consistent tile production, minimizing the margin for error and ensuring top-notch quality in every tile. The machine also boasts a high production capacity, significantly increasing output and reducing lead times for manufacturers. This not only improves efficiency but also allows manufacturers to meet the growing demand for stone-coated metal roof tiles in a timely manner.Another notable advantage of this innovative machine is its cost-effectiveness. By streamlining the production process and increasing output, manufacturers can reduce their operational costs and improve their overall profitability. The machine also requires minimal maintenance, further contributing to cost savings in the long run. Additionally, the high-quality output of the machine can enhance the reputation of manufacturers, helping them attract more customers and secure lucrative contracts.Furthermore, the Stone Coated Metal Roof Tile Making Machine is designed with sustainability in mind. It utilizes energy-efficient technologies and minimizes material waste, making it an environmentally friendly choice for manufacturers. This aligns with the growing emphasis on sustainability in the construction industry and can be a valuable selling point for manufacturers looking to appeal to eco-conscious customers.In addition to the impressive capabilities of the Stone Coated Metal Roof Tile Making Machine, the company behind this groundbreaking innovation has a strong track record of excellence in the industry. With years of experience in machinery manufacturing, they have gained a reputation for delivering high-quality and reliable solutions for their clients. Their commitment to innovation and customer satisfaction sets them apart as a leading player in the market, and their Stone Coated Metal Roof Tile Making Machine is a testament to their expertise and dedication to advancing the industry.In conclusion, the Stone Coated Metal Roof Tile Making Machine is a game-changer for manufacturers in the roofing industry. With its advanced technology, high efficiency, and cost-effectiveness, this innovative machine offers a competitive edge for manufacturers looking to stay ahead in the market. Backed by a reputable and experienced company, it is poised to transform the production process of stone-coated metal roof tiles and set new standards for quality and performance in the industry.

High-Quality Metal Roll Forming Machine for Efficient Production

Metal Roll Forming Machine Revolutionizes Manufacturing IndustryWith the continuous development of the manufacturing industry, the demand for efficient and high-quality equipment is ever increasing. In response to this need, {company} has introduced a revolutionary metal roll forming machine that is set to transform the way metal products are manufactured.The metal roll forming machine, designed and developed by {company}, is a state-of-the-art piece of equipment that is capable of seamlessly shaping metal sheets into various profiles and designs. This innovative machine is equipped with advanced technology and features a precision control system that allows for the production of high-quality and accurate metal products.One of the key advantages of {company}'s metal roll forming machine is its versatility. It has the ability to produce a wide range of metal products, including roofing panels, wall cladding, steel framing, and various other components used in the construction and manufacturing industry. This versatility makes it an invaluable asset for companies involved in metal fabrication and manufacturing.In addition to its versatility, the metal roll forming machine boasts impressive speed and efficiency. It is capable of producing large volumes of metal products in a relatively short amount of time, without compromising on quality. This makes it an ideal solution for companies looking to streamline their manufacturing processes and improve their overall productivity.Furthermore, {company}'s metal roll forming machine is designed with user convenience in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and maintain. This ensures that operators can quickly adapt to using the machine and maximize its performance from the get-go.The introduction of this cutting-edge metal roll forming machine marks a significant milestone for {company}, as it further solidifies their position as a leader in the manufacturing equipment industry. Leveraging their expertise and industry knowledge, {company} has successfully developed a machine that addresses the evolving needs of the manufacturing sector.The metal roll forming machine is a testament to {company}'s commitment to innovation and continuous improvement. By investing in research and development, {company} has been able to create a product that not only meets the current demands of the market but also sets new standards for efficiency and quality in metal manufacturing.As the manufacturing industry continues to evolve, the introduction of {company}'s metal roll forming machine is set to have a profound impact on how metal products are produced. Its versatility, speed, and user-friendly design make it a valuable asset for companies looking to stay ahead in a competitive market.Looking ahead, {company} remains dedicated to pushing the boundaries of innovation and delivering solutions that empower manufacturers to achieve their production goals. With the metal roll forming machine, {company} is taking manufacturing to new heights, revolutionizing the industry and setting a new standard for excellence.

High-Quality Roof Making Machine for Efficient Roofing

Roof Making Machine Revolutionizes Roofing IndustryThe roofing industry has seen a remarkable rise in innovation and efficiency with the introduction of the Roof Making Machine by a leading manufacturing company. This cutting-edge technology has quickly become the go-to solution for roofing professionals, offering unprecedented speed and precision in the production of high-quality roofs.The Roof Making Machine is a state-of-the-art piece of equipment that is designed to streamline the entire process of roof manufacturing. It is capable of producing a wide range of roofing materials, including asphalt shingles, metal panels, and even clay and concrete tiles. This versatility makes it an indispensable tool for roofing companies of all sizes.One of the key features of the Roof Making Machine is its ability to produce roofs at an incredibly fast pace. Traditional methods of roof manufacturing can be time-consuming and labor-intensive, often leading to extended production times and delays in project completion. However, with the Roof Making Machine, companies can significantly reduce their production timelines, enabling them to take on more projects and increase their overall efficiency.In addition to speed, the Roof Making Machine also offers unparalleled accuracy and precision. The advanced technology and automated processes ensure that each roofing material is manufactured to exact specifications, resulting in a consistent and high-quality end product. This level of precision is crucial in the roofing industry, where even the smallest discrepancies can result in costly rework and repairs.Furthermore, the Roof Making Machine is designed with user-friendly features, making it accessible to a wide range of roofing professionals. Its intuitive interface and streamlined operation allow operators to quickly familiarize themselves with the machine, maximizing productivity and reducing the learning curve associated with new equipment.The company behind the Roof Making Machine has a long-standing reputation for excellence in the manufacturing industry. With a commitment to innovation and customer satisfaction, they have consistently delivered top-tier products that meet the evolving needs of the market. Their expertise in engineering and technology has played a significant role in the development of the Roof Making Machine, and their dedication to quality ensures that it exceeds industry standards.The Roof Making Machine has already made a substantial impact on the roofing industry, with companies of all sizes incorporating this technology into their operations. Its ability to increase production output, improve accuracy, and streamline processes has made it a game-changing solution for modern roofing professionals. As the demand for high-quality roofing materials continues to grow, the Roof Making Machine is poised to become an indispensable tool for companies looking to stay ahead of the competition.In conclusion, the Roof Making Machine represents a monumental shift in the roofing industry, offering a combination of speed, precision, and efficiency that was previously unthinkable. With its advanced features and user-friendly design, it has the potential to revolutionize the way roofs are manufactured, setting a new standard for quality and production in the industry. As more companies adopt this groundbreaking technology, the impact of the Roof Making Machine is sure to resonate throughout the entire roofing sector, shaping the future of the industry for years to come.