High-quality Carbon Steel Coil for Industrial Use

By:Admin

The carbon steel coil that {} has developed is made from the finest quality materials and has been engineered to meet the highest standards of performance and reliability. This new product is designed to be used in a wide range of applications, including construction, manufacturing, automotive, and many others. In addition, the carbon steel coil is available in various thicknesses and widths, making it suitable for a diverse array of projects and requirements.

One of the key features of the carbon steel coil is its exceptional strength and durability. This product has been specifically crafted to withstand the rigors of heavy-duty use, and is capable of withstanding high levels of stress and pressure without sacrificing its structural integrity. This makes it an ideal choice for demanding applications where reliability and performance are paramount.

In addition to its strength and durability, the carbon steel coil also offers excellent versatility and ease of use. It can be easily formed, welded, and cut to meet the specific requirements of a given project, and can be readily adapted to suit a wide variety of applications. This makes it an extremely cost-effective solution, as it reduces the need for additional processing and fabrication, saving both time and money.

Furthermore, {} is proud to highlight the environmental credentials of their new carbon steel coil. The company is committed to sustainability and has taken great care to ensure that this product is manufactured in an environmentally responsible manner. The production process for the carbon steel coil minimizes waste and energy consumption, and the product itself is fully recyclable, making it an eco-friendly choice for environmentally conscious customers.

{} is confident that their new carbon steel coil will set a new standard for quality and performance in the industry. The company has a long-standing reputation for excellence, and this latest addition to their product line is a testament to their ongoing commitment to innovation and customer satisfaction. With this new product, {} is well positioned to meet the evolving needs of their customers and provide them with the best steel solutions on the market.

To learn more about the new carbon steel coil from {}, or to inquire about placing an order, please visit their website or contact their sales team directly. With their extensive expertise and dedication to customer service, they will be happy to assist with any inquiries and provide further details about this exciting new product.

Company News & Blog

Efficient Roll Forming Machine for Partial Arc Glazed Tiles

Title: Innovation in Partial Arc Glazed Tile Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:In a remarkable breakthrough in the roofing industry, a leading machinery manufacturer has recently unveiled the latest version of its Partial Arc Glazed Tile Roll Forming Machine. This innovative technology has the potential to transform the way glazed tiles are produced, providing enhanced efficiency, durability, and aesthetics.Company Background:With decades of experience in the field, the company has become a renowned name in the manufacturing and supply of top-quality roll forming machines. It has solidified its position as an industry leader by consistently introducing cutting-edge solutions that cater to the evolving needs of the roofing sector.1. Overview of the Partial Arc Glazed Tile Roll Forming Machine:The latest iteration of the Partial Arc Glazed Tile Roll Forming Machine is the result of extensive research and development. This advanced machine is engineered to handle the production of glazed tiles with exceptional precision, ensuring consistent quality and reducing the chances of defects.2. Enhanced Efficiency and Productivity:The technology integrated into the new machine enables a significant increase in production speed as compared to previous models. With improved automation and optimized processes, manufacturers can expect higher output rates, reducing production downtime and improving overall efficiency.3. Durability and Longevity:Utilizing high-quality materials and state-of-the-art manufacturing techniques, the Partial Arc Glazed Tile Roll Forming Machine ensures the production of tiles that are resilient and built to last. The machine is designed to withstand prolonged use, reducing the need for frequent maintenance and ensuring long-term reliability.4. Aesthetic Appeal:Recognizing the importance of aesthetics in the roofing industry, the machine offers immense design flexibility. It enables manufacturers to produce glazed tiles in various sizes, colors, and finishes, allowing for customization according to different architectural styles and consumer preferences.5. Streamlined Workflow and Ease of Use:The intuitive user interface of the Partial Arc Glazed Tile Roll Forming Machine simplifies the manufacturing process, empowering operators with enhanced control and monitoring capabilities. Integration with computerized systems makes it easier to adjust parameters, track production progress, and quickly troubleshoot any issues that may arise.6. Emphasis on Quality Assurance and Safety:The new roll forming machine incorporates advanced quality control mechanisms, enabling real-time monitoring and inspection of the tiles being produced. By identifying potential defects early in the process, manufacturers can ensure that only flawless products are delivered to their customers. Furthermore, strict adherence to safety standards ensures a secure working environment for operators.7. Environmental Considerations:Reducing the environmental footprint is a key priority for the company, and the new machine embodies this commitment. By optimizing energy consumption and minimizing waste generation, it adheres to sustainable manufacturing practices, aligning with current environmental regulations.8. Positive Impact on the Roofing Industry:The introduction of the Partial Arc Glazed Tile Roll Forming Machine will undoubtedly revolutionize the roofing industry. Its advanced features and capabilities will help manufacturers enhance their competitiveness by offering superior products to meet the growing demands in the market. The increased efficiency and productivity will not only benefit manufacturers but also result in shorter turnaround times and cost savings for end-consumers.Conclusion:The latest iteration of the Partial Arc Glazed Tile Roll Forming Machine is a game-changer in the roofing industry. With its superior technology, production efficiency, aesthetic appeal, and focus on quality assurance, it promises to elevate the standards of tile manufacturing. This innovation demonstrates the company's commitment to providing cutting-edge solutions and driving forward the industry through innovation.

Innovative Double Layer Roll Forming Machine in Chile

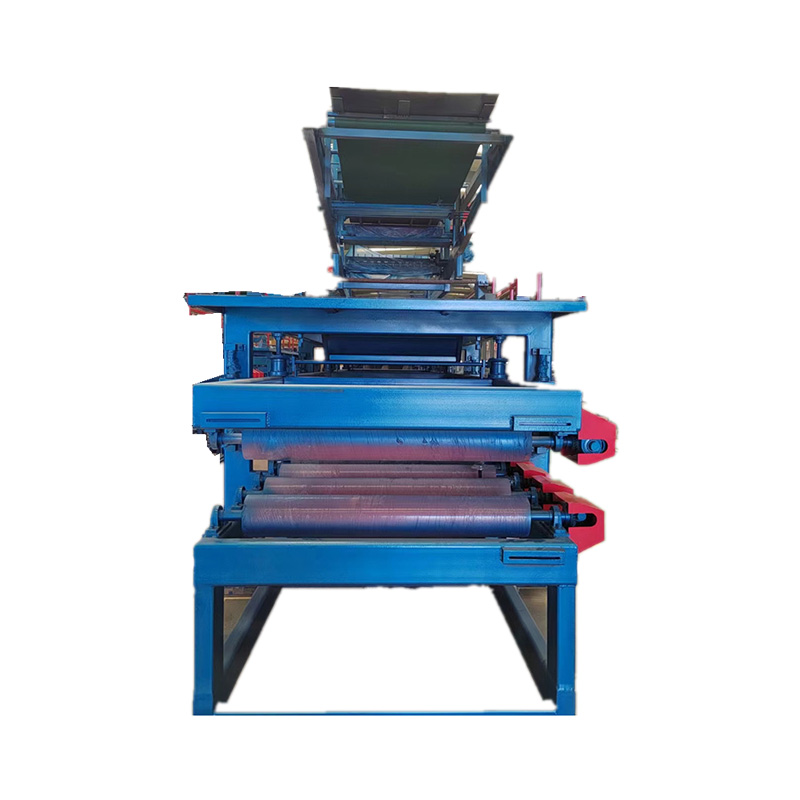

Chile Double Layer Roll Forming Machine is set to revolutionize the manufacturing industry in Chile with its innovative technology and cutting-edge capabilities. The machine, manufactured by a leading international company in the field of roll forming equipment, is designed to significantly improve production efficiency and output, making it a game-changer for businesses in the region.With the Chile Double Layer Roll Forming Machine, companies can expect increased productivity and cost savings, thanks to its advanced features and functionalities. The machine is capable of producing double-layer metal sheets with precision and speed, allowing for seamless and efficient manufacturing processes. This will undoubtedly benefit businesses across various industries, including construction, automotive, and engineering, among others.The company behind the development of the Chile Double Layer Roll Forming Machine is a renowned leader in the global roll forming equipment market, with a strong track record of delivering high-quality and reliable machinery. With decades of experience and expertise in the field, the company is committed to providing state-of-the-art solutions to its customers, helping them stay ahead of the competition and meet the demands of an ever-evolving market.One of the key advantages of the Chile Double Layer Roll Forming Machine is its versatility. The machine is capable of handling a wide range of materials, including steel, aluminum, and other metals, making it suitable for various manufacturing needs. Whether it's producing roofing sheets, wall panels, or other metal components, the machine offers unmatched flexibility and performance, making it an indispensable asset for businesses in Chile.In addition to its advanced capabilities, the Chile Double Layer Roll Forming Machine is also designed with user-friendly features, ensuring ease of operation and maintenance. This is essential for businesses looking to streamline their production processes and minimize downtime, ultimately leading to improved overall efficiency and profitability. With minimal training and support requirements, the machine allows operators to quickly adapt to its operation, maximizing its potential from day one.Furthermore, the company is dedicated to providing comprehensive support and service to its customers in Chile, ensuring that they get the most out of their investment in the Chile Double Layer Roll Forming Machine. From installation and training to ongoing maintenance and technical assistance, the company's team of experts is committed to delivering top-notch support, helping customers optimize their manufacturing operations and achieve long-term success.The introduction of the Chile Double Layer Roll Forming Machine is expected to have a significant impact on the manufacturing landscape in Chile, empowering businesses to enhance their production capabilities and meet the growing demands of the market. With its advanced technology, versatility, and user-friendly design, the machine represents a major leap forward for the industry, setting new standards for efficiency, quality, and performance.As businesses in Chile look to stay competitive and adapt to the changing dynamics of the market, the Chile Double Layer Roll Forming Machine offers a compelling solution to their manufacturing needs. With its cutting-edge features and the backing of a reputable international company, the machine is poised to become a cornerstone of the industry, driving growth and innovation for years to come.

High-Quality Cement Roof Tile Making Machine - Everything You Need to Know

Cement Roof Tile Making Machine Revolutionizing the Roofing IndustryThe roofing industry has been revolutionized by the innovative technology of the Cement Roof Tile Making Machine. This advanced machine has completely transformed the production process of cement roof tiles, making it more efficient, cost-effective, and environmentally friendly.The Cement Roof Tile Making Machine, developed by an industry-leading company, has quickly established itself as a game-changer in the roofing sector. With its cutting-edge technology and precision engineering, the machine has set new standards for the production of high-quality cement roof tiles.The company behind this groundbreaking technology, with years of experience and expertise in the manufacturing and construction industry, has gained a stellar reputation for delivering top-notch machinery and equipment. Their commitment to innovation and excellence has propelled them to the forefront of the market, and the Cement Roof Tile Making Machine is a testament to their dedication to pushing the boundaries of what is possible in the industry.One of the key features that sets the Cement Roof Tile Making Machine apart from conventional tile production methods is its high level of automation. Through state-of-the-art robotics and computerized systems, the machine is capable of producing cement roof tiles with unparalleled precision and consistency. This not only ensures the quality of the tiles but also significantly increases the production capacity, allowing for faster turnaround times and higher output.Furthermore, the machine has been designed with sustainability in mind. It is equipped with energy-efficient components and optimized manufacturing processes to minimize waste and reduce environmental impact. This aligns with the company's commitment to promoting eco-friendly practices and contributing to a greener, more sustainable future for the construction industry.In addition to its technological advancements, the Cement Roof Tile Making Machine also boasts a user-friendly interface and easy maintenance, making it accessible to a wide range of manufacturers and roofing professionals. The company provides comprehensive training and support to ensure that customers can fully leverage the capabilities of the machine and maximize their productivity.The impact of the Cement Roof Tile Making Machine on the roofing industry has been nothing short of transformative. It has empowered manufacturers to elevate the quality of their products, streamline their operations, and meet the growing demand for durable and aesthetically pleasing cement roof tiles.The benefits of the machine extend beyond the manufacturing process, as it ultimately translates to better roofing solutions for residential, commercial, and industrial properties. High-quality cement roof tiles produced by the machine offer superior durability, fire resistance, and thermal insulation, providing long-lasting protection and value to buildings.The company's dedication to innovation and excellence has garnered widespread recognition and trust from customers around the world. Their commitment to continuous improvement and customer satisfaction has positioned them as a go-to provider of advanced machinery and equipment for the construction and manufacturing sectors.Looking ahead, the company remains committed to pushing the boundaries of technological innovation and setting new benchmarks for the industry. With a focus on sustainability, efficiency, and quality, they are poised to continue driving positive change and shaping the future of the roofing industry with game-changing solutions like the Cement Roof Tile Making Machine.

High-Quality Corrugated Roof Sheet Making Machine for Sale - A Complete Guide

Corrugated Roof Sheet Making Machine Revolutionizing Roofing IndustryThe roofing industry has seen a significant transformation with the introduction of advanced technology and machinery. One company at the forefront of this innovation is {company name}, a leading manufacturer of Corrugated Roof Sheet Making Machines. This state-of-the-art equipment has revolutionized the production of corrugated roof sheets, offering greater efficiency, speed, and precision.{Company name} has been a pioneer in the manufacturing of Corrugated Roof Sheet Making Machines for several years. The company's commitment to research and development has led to the creation of cutting-edge machinery that has transformed the way roof sheets are produced. The Corrugated Roof Sheet Making Machine is designed to meet the increasing demand for high-quality roofing materials in the construction industry.The Corrugated Roof Sheet Making Machine manufactured by {company name} is highly versatile, capable of producing a wide range of corrugated roof sheets with varying thicknesses and dimensions. This flexibility allows roofing manufacturers to cater to diverse customer needs and preferences. Moreover, the machine's intuitive controls and automation features help streamline the production process, reducing labor costs and minimizing human error.One of the key advantages of the Corrugated Roof Sheet Making Machine is its high production capacity. The machine is capable of churning out a large volume of roof sheets in a relatively short period, thereby boosting overall output and meeting tight project deadlines. This efficiency is essential for roofing companies looking to stay competitive in the market.In addition to its speed and capacity, the Corrugated Roof Sheet Making Machine ensures exceptional precision and accuracy in the manufacturing process. The machine is equipped with advanced technology that guarantees uniformity in the dimensions and quality of the produced roof sheets. This level of consistency is crucial for ensuring the structural integrity and durability of the roofing material.Another notable feature of the Corrugated Roof Sheet Making Machine is its durability and reliability. Constructed from high-quality materials and incorporating robust components, the machine is designed to withstand continuous and demanding operation. This means that roofing manufacturers can rely on the machine to deliver consistent performance over an extended period, without experiencing frequent downtime or maintenance issues.Furthermore, {company name} provides comprehensive technical support and after-sales services for its Corrugated Roof Sheet Making Machines. The company's team of skilled engineers and technicians are readily available to assist customers with installation, training, maintenance, and troubleshooting. This commitment to customer satisfaction ensures that roofing manufacturers can maximize the potential of the machine and minimize disruptions to their production workflow.The impact of the Corrugated Roof Sheet Making Machine extends beyond just the manufacturing process. The machine also contributes to the sustainability of the roofing industry by optimizing material usage and minimizing waste. With its precise cutting and shaping capabilities, the machine helps reduce unnecessary resource consumption and promotes eco-friendly practices.With the Corrugated Roof Sheet Making Machine, {company name} has set a new benchmark for excellence in the roofing industry. The machine's exceptional performance, efficiency, and reliability have positioned it as a game-changer for roofing manufacturers worldwide. As the demand for high-quality roofing materials continues to grow, the Corrugated Roof Sheet Making Machine is poised to play a pivotal role in shaping the future of the industry.

Top Roofing Sheet Machine: Everything You Need to Know

Roofing Sheet Machine Revolutionizes Manufacturing Industry{Company Name}, a leading provider of innovative manufacturing solutions, has recently unveiled their latest innovation, the Roofing Sheet Machine. This state-of-the-art machine has the ability to drastically improve the efficiency and quality of roofing sheet production, offering a game-changing solution for the manufacturing industry.The Roofing Sheet Machine is designed to streamline the manufacturing process of roofing sheets, which are essential components for building construction. With its advanced technology and cutting-edge features, this machine is set to revolutionize the way roofing sheets are produced.One of the key features of the Roofing Sheet Machine is its high-speed production capability. The machine is capable of producing a large volume of roofing sheets in a short amount of time, significantly increasing production output and reducing lead times. This improved efficiency will not only benefit manufacturers by allowing them to meet tight deadlines and customer demands, but also create cost savings in the long run.In addition to its speed, the Roofing Sheet Machine also boasts exceptional precision and accuracy. The machine is equipped with advanced sensors and control systems that ensure each roofing sheet is manufactured to exact specifications, resulting in consistent quality and uniformity. This level of precision is crucial in the manufacturing of roofing sheets, where accuracy and reliability are paramount.Furthermore, the Roofing Sheet Machine is designed with versatility in mind. It has the capability to produce a wide range of roofing sheet designs and sizes, making it a flexible solution for manufacturers with diverse product offerings. This versatility allows manufacturers to easily adapt to changing market demands and offer a variety of roofing sheet options to their customers.{Company Name} has a long-standing reputation for delivering innovative and reliable manufacturing solutions. With a strong commitment to research and development, the company continuously strives to push the boundaries of technology and engineering. The Roofing Sheet Machine is a testament to {Company Name}'s dedication to driving progress and innovation in the manufacturing industry."We are thrilled to introduce the Roofing Sheet Machine to the market," said {Spokesperson}, CEO of {Company Name}. "This machine represents a significant advancement in roofing sheet production, and we believe it will have a profound impact on the industry. Our team has worked tirelessly to develop a machine that not only improves efficiency and quality, but also offers unprecedented versatility. We are confident that the Roofing Sheet Machine will set a new standard for manufacturing in the roofing industry."As the manufacturing industry continues to evolve, innovative solutions like the Roofing Sheet Machine are essential for driving progress and meeting the demands of a rapidly changing market. With its cutting-edge technology and advanced capabilities, the Roofing Sheet Machine is poised to become a game-changer for manufacturers in the roofing industry.{Company Name}'s commitment to excellence and innovation has positioned them as a leader in the manufacturing industry, and the Roofing Sheet Machine is a testament to their ongoing dedication to pushing the boundaries of what is possible in manufacturing technology. As the Roofing Sheet Machine becomes more widely adopted, it is expected to have a significant impact on the industry, improving efficiency, quality, and ultimately, the bottom line for manufacturers around the world.

Revolutionary Standing Seam Roll Formers: Empowering the Metal Roofing Industry

[Insert Company Name] Launches Cutting-edge Standing Seam Roll Former to Revolutionize Metal Roofing[City, State] - [Insert Company Name], a leading provider of innovative manufacturing solutions, is proud to announce the launch of their latest product, the standing seam roll former (name removed). With state-of-the-art technology and unmatched precision, this cutting-edge machine is set to revolutionize the metal roofing industry.Metal roofing has gained immense popularity in recent years due to its durability, cost-effectiveness, and aesthetic appeal. Standing seam roofs, in particular, have become a preferred choice for many homeowners and businesses. However, the traditional manufacturing methods for standing seam panels often rely on manual labor, resulting in longer production timelines and increased costs.Recognizing the need for a more efficient solution, [Insert Company Name] developed the standing seam roll former. This innovative machine automates the entire fabrication process, significantly reducing production time and cutting down labor costs. It leverages advanced technology to deliver precise and consistent panel profiles, ensuring superior quality in each roll.The standing seam roll former from [Insert Company Name] is equipped with cutting-edge features that make it stand out in the market. Its robust construction and high-grade materials ensure durability and longevity, providing businesses with a reliable long-term investment. The machine's user-friendly interface and intuitive controls make it easy for operators to set up and operate, minimizing training time and the potential for errors.The standing seam roll former boasts a streamlined design, ensuring efficient use of space in any manufacturing facility. Its compact size allows for easy installation and maneuverability, optimizing workflow and productivity. Furthermore, the machine's integrated safety features prioritize operator well-being, adhering to the highest industry standards.One notable feature of the standing seam roll former is its versatility. With adjustable settings, the machine can accommodate varying panel widths and seam heights, catering to the diverse needs of metal roofing projects. This adaptability offers businesses the flexibility to meet customer specifications while maintaining efficiency and productivity.Additionally, [Insert Company Name] provides comprehensive customer support to further enhance the value of their standing seam roll former. Their team of expert technicians is available to assist with installation, training, and ongoing maintenance, ensuring that businesses get the most out of their investment. With their commitment to customer satisfaction, [Insert Company Name] aims to establish long-lasting partnerships with metal roofing manufacturers worldwide.Several prominent metal roofing companies have already expressed excitement about the standing seam roll former from [Insert Company Name]. They recognize the potential for increased productivity, improved quality, and cost savings that this cutting-edge machine offers. The initial feedback from these industry leaders has been overwhelmingly positive, reinforcing [Insert Company Name]'s position as a trusted provider of innovative manufacturing solutions.[Insert Company Name]'s launch of the standing seam roll former is a significant milestone for the metal roofing industry. This groundbreaking machine has the potential to revolutionize the way standing seam panels are manufactured, accelerating production timelines, reducing costs, and setting new standards of quality and efficiency.About [Insert Company Name]:[Insert Company Name] is a leading manufacturer of advanced manufacturing solutions for a wide range of industries. With a focus on innovative technology and exceptional customer service, [Insert Company Name] aims to empower businesses to achieve enhanced productivity, cost-effectiveness, and quality. Their extensive product range includes cutting-edge machines for metal fabrication, forming, and more, making them a go-to choice for companies looking to stay ahead in the highly competitive manufacturing sector.For more information about [Insert Company Name] and their standing seam roll former, please visit [website] or contact [contact information].Media Contact:[Your Name][Position][Email][Phone Number]

High-quality Corrugated Roll Forming Machine for Efficient Production

[Company Name] introduces advanced corrugated roll forming machine[City, Date] – [Company Name], a leading manufacturer of roll forming equipment, has recently launched an advanced corrugated roll forming machine that is set to revolutionize the industry. The new machine is designed to increase productivity, reduce material waste, and improve the overall quality of corrugated products.The [Company Name] corrugated roll forming machine is equipped with the latest technology and features a high-speed roller and precision control system that ensures consistent and accurate production. The machine also boasts a user-friendly interface, making it easy to operate and maintain.With the introduction of this new machine, [Company Name] aims to provide its customers with a solution that addresses the challenges faced in the corrugated industry. The machine is capable of producing a wide range of corrugated products, including roofing panels, wall cladding, and decking, with exceptional speed and efficiency.The [Company Name] corrugated roll forming machine is also designed to minimize material waste, thanks to its precise cutting and forming capabilities. This not only helps to reduce production cost but also contributes to environmental sustainability.In addition to its cutting-edge technology, the [Company Name] corrugated roll forming machine is backed by the company’s commitment to customer support and service. The company’s team of experienced engineers and technicians are available to provide training, technical assistance, and maintenance services, ensuring that customers get the most out of their investment.[Company Name] has a long-standing reputation for delivering high-quality and reliable roll forming equipment. The company’s commitment to innovation and customer satisfaction has made it a trusted partner for businesses in the metal forming industry.“We are excited to introduce our new corrugated roll forming machine to the market,” said [Spokesperson Name], [Position at Company]. “We believe that this machine will set a new standard for productivity, quality, and efficiency in the corrugated industry. Our team has put a lot of effort into developing this machine, and we are confident that it will meet the needs of our customers and help them stay ahead in a competitive market.”The introduction of the new corrugated roll forming machine is a testament to [Company Name]’s commitment to delivering innovative solutions that drive customer success. The company’s dedication to research and development, combined with its team of experts, ensures that it continues to lead the way in the roll forming industry.With its advanced technology, precision engineering, and exceptional customer support, the [Company Name] corrugated roll forming machine is set to make a significant impact on the industry. Businesses in the corrugated industry can now look forward to increased productivity, improved quality, and reduced material waste, thanks to this groundbreaking machine from [Company Name]. For more information about the [Company Name] corrugated roll forming machine, or to schedule a demonstration, please visit [company website] or contact [company contact information].About [Company Name]:[Company Name] is a leading manufacturer of roll forming equipment, specializing in providing innovative solutions for the metal forming industry. With a focus on quality, reliability, and customer satisfaction, the company has earned a reputation as a trusted partner for businesses looking to enhance their manufacturing processes. [Company Name] is committed to delivering cutting-edge technology and exceptional service to help its customers stay ahead in a competitive market.

How to Build a Sheet Metal Machine for Corrugated Iron Production

[Company Introduction]Company XYZ is a leading manufacturer in the industrial machinery sector, specializing in the design, development, and production of advanced equipment for various applications. With years of experience and a dedicated team of experts, we have emerged as a trusted name in the industry, providing innovative solutions to our clients worldwide.Our company is committed to delivering high-quality, reliable, and cost-effective machinery, catering to the unique requirements of our customers. We strive to stay ahead of the curve by investing in research and development to ensure our products are at the forefront of technological advancements in the market.In line with our commitment to excellence and customer satisfaction, we are excited to introduce our latest breakthrough product, the Calaminas Manufacturing Machine. Designed to revolutionize the manufacturing process of calaminas, this state-of-the-art equipment offers numerous benefits and efficiency improvements for industrial production.[News Content]Title: Advanced Manufacturing Machine Set to Transform Calaminas Production[Location], [Date] - Company XYZ, a leading industrial machinery manufacturer, unveiled its revolutionary Calaminas Manufacturing Machine today, promising to redefine the process of producing high-quality calaminas with unprecedented efficiency and precision. This groundbreaking equipment is set to transform the construction and industrial sectors, benefiting businesses worldwide.Calaminas, also known as corrugated iron sheets, are extensively used in building roofs, walls, and other construction applications due to their durability, weather resistance, and cost-effectiveness. However, traditional calaminas manufacturing methods have often been associated with inefficiencies, high production costs, and quality inconsistencies.Addressing these challenges, Company XYZ's Calaminas Manufacturing Machine combines cutting-edge technology with years of industry expertise. The machine incorporates automated processes and advanced features, streamlining production while ensuring consistent quality and reducing costs significantly.One of the key advantages of the Calaminas Manufacturing Machine is its ability to handle a wide range of raw materials, including various grades of metal sheets and alloys. This flexibility allows manufacturers to cater to diverse client demands while maintaining optimum production levels.Furthermore, the machine's automated processes eliminate the need for manual labor, reducing the risk of human error and increasing overall productivity. The advanced control system integrated into the machine monitors and adjusts various parameters throughout the production process, ensuring precise results with minimal wastage.Another noteworthy feature of the Calaminas Manufacturing Machine is its quick setup and changeover capabilities. Manufacturers can easily switch between different calaminas designs and dimensions, reducing downtime significantly. This ensures increased production efficiency and faster turnaround times for orders, contributing to a more agile and responsive supply chain.Moreover, the machine's robust construction and durable components ensure long-term reliability and minimal maintenance requirements. It is designed to withstand the demands of continuous production operations while minimizing the potential for breakdowns and costly downtime.The introduction of Company XYZ's Calaminas Manufacturing Machine is set to drive significant improvements in the calaminas industry, benefiting manufacturers in terms of increased production efficiency, enhanced quality control, and reduced operational costs. The innovative nature of this equipment positions Company XYZ as a frontrunner in the industrial machinery sector, further strengthening its reputation as a trusted industry partner.In conclusion, the launch of Company XYZ's Calaminas Manufacturing Machine marks a significant milestone, revolutionizing the production of calaminas with its cutting-edge technology, automated processes, and enhanced efficiency. The introduction of this advanced equipment is set to reshape the calaminas industry, empowering manufacturers to meet growing market demands while maintaining a competitive edge in today's dynamic business environment.

High-Quality Glazed Tile Roll Forming Machine for Sale

Glazed Tile Roll Forming Machine Market Growth and Company IntroductionThe global glazed tile roll forming machine market is expected to experience significant growth in the coming years, according to a recent report by Market Research Future. This growth is attributed to the increasing demand for glazed tiles in the construction industry, particularly in emerging economies. Glazed tiles are known for their durability, aesthetic appeal, and resistance to water and stains, making them a popular choice for both residential and commercial buildings.One of the key players in the glazed tile roll forming machine market is a leading manufacturing company that specializes in the production of advanced roll forming equipment. With a strong focus on innovation and quality, the company has established itself as a trusted provider of roll forming machines for a wide range of applications, including the production of glazed tiles.The company's glazed tile roll forming machine is designed to deliver high precision and efficiency, allowing manufacturers to produce a wide variety of glazed tile profiles with ease. The machine is equipped with advanced features such as automatic control systems, quick-change roll forming tools, and energy-efficient operation. These capabilities enable manufacturers to meet the growing demand for glazed tiles while improving productivity and reducing production costs.In addition to its technical capabilities, the company's glazed tile roll forming machine is also backed by a comprehensive after-sales support system. This includes installation and training services, as well as ongoing maintenance and technical assistance to ensure smooth and reliable operation of the equipment.The company's commitment to excellence extends beyond its products and services to its dedication to sustainability and environmental responsibility. By investing in research and development, the company continuously strives to improve the energy efficiency and environmental performance of its roll forming machines, aligning with the industry's increasing focus on sustainable manufacturing practices.With a strong presence in the global market, the company has successfully supplied its glazed tile roll forming machines to customers in diverse geographical regions. Its reputation for delivering high-quality, reliable, and cost-effective solutions has earned the trust of leading manufacturers in the construction industry.Looking ahead, the company remains focused on addressing the evolving needs of the market and staying at the forefront of technological advancements. By leveraging its expertise and experience, the company is well-positioned to capitalize on the growing demand for glazed tile roll forming machines and maintain its leadership in the industry.In conclusion, the glazed tile roll forming machine market is poised for significant growth, driven by increasing demand for glazed tiles in the construction industry. With a strong emphasis on innovation, quality, and sustainability, the company is well-equipped to meet the needs of manufacturers and contribute to the advancement of the global construction market.As the market continues to evolve, the company remains committed to delivering cutting-edge solutions and exceeding customer expectations, solidifying its reputation as a premier provider of glazed tile roll forming machines. With a strong track record of success and a clear vision for the future, the company is poised to play a pivotal role in shaping the future of the glazed tile roll forming machine market.

High-quality EPS Roll Forming Machine for Efficient Production

Eps Roll Forming Machine Revolutionizes Roofing IndustryThe roofing industry has seen a significant transformation with the introduction of the EPS Roll Forming Machine. This innovative machine is revolutionizing the way roofing materials are manufactured and has set a new standard for efficiency and productivity in the industry.The EPS Roll Forming Machine is a state-of-the-art piece of equipment that is designed to fabricate roofing materials with unparalleled precision and speed. This machine is capable of producing a wide range of roofing components, including corrugated panels, eave trims, ridge caps, and more. With its advanced technology and high-speed capabilities, the EPS Roll Forming Machine has quickly become the go-to choice for roofing manufacturers looking to streamline their production processes.One of the key features that sets the EPS Roll Forming Machine apart from traditional manufacturing methods is its ability to produce roofing materials on-site. This eliminates the need for manufacturers to outsource their production, saving time and money in the long run. Additionally, the machine's flexibility allows for quick adjustments and customization, making it easy to adapt to changing market demands and customer preferences.In addition to its impressive performance, the EPS Roll Forming Machine is also highly efficient, boasting a low energy consumption and minimal material waste. This not only contributes to cost savings for manufacturers but also aligns with a growing emphasis on sustainability and eco-friendly production practices in the industry.The company behind this groundbreaking innovation, {}, has been a leading provider of roll forming solutions for over a decade. With a focus on delivering cutting-edge technology and exceptional customer service, the company has earned a reputation for excellence in the roofing and construction industries.{} offers a comprehensive range of roll forming machines, including the EPS Roll Forming Machine, to meet the diverse needs of their clients. Their team of experts works closely with customers to understand their specific requirements and provide customized solutions that enhance their production capabilities.The success of the EPS Roll Forming Machine is a testament to the commitment and ingenuity of the team at {}. By staying at the forefront of technological advancements and continuously refining their products, the company has solidified its position as a trusted partner for roofing manufacturers worldwide.The introduction of the EPS Roll Forming Machine has already made a significant impact on the roofing industry, and its potential is limitless. As demand for efficient and sustainable manufacturing solutions continues to grow, it is clear that this innovative machine will play a pivotal role in shaping the future of roofing production.In conclusion, the EPS Roll Forming Machine has set a new standard for efficiency, precision, and sustainability in the roofing industry. With its cutting-edge technology and impressive capabilities, this innovative machine is reshaping the way roofing materials are manufactured and is poised to drive continued advancements in the industry. As the demand for high-quality, cost-effective roofing solutions continues to rise, the EPS Roll Forming Machine and the company behind it are well-positioned to lead the way forward.