Lightweight and Durable Aluminium Foam Panel for Various Applications

By:Admin

The unique combination of aluminum and foam creates a material that is not only incredibly strong, but also lightweight and easy to work with. This makes Aluminium Foam Panel ideal for a variety of construction projects, from simple renovations to complex architectural designs. The panels are highly customizable, allowing for endless design possibilities and ensuring that each project is truly unique.

One of the key benefits of Aluminium Foam Panel is its thermal insulation properties. The foam core of the panel provides excellent insulation, helping to regulate temperature and reduce energy costs. This makes Aluminium Foam Panel an eco-friendly choice for environmentally conscious builders and homeowners.

In addition to its insulation properties, Aluminium Foam Panel also offers soundproofing benefits. The foam core absorbs sound, making it an ideal choice for buildings in noisy urban areas or locations with high levels of ambient noise. This makes Aluminium Foam Panel an attractive option for commercial buildings, residential homes, and other structures where noise control is a priority.

The durability of Aluminium Foam Panel is another major selling point. The aluminum outer layer provides protection against the elements, making it resistant to corrosion, rust, and other forms of degradation. This ensures that buildings constructed with Aluminium Foam Panel will stand the test of time, requiring minimal maintenance and delivering long-lasting performance.

One company at the forefront of Aluminium Foam Panel production and innovation is {}. With a focus on research and development, the company has been able to push the boundaries of what is possible with this revolutionary material. By harnessing the unique properties of aluminum and foam, they have developed a range of panel options that meet the needs of modern construction projects.

Furthermore, {} has also invested in state-of-the-art manufacturing processes, ensuring that their Aluminium Foam Panel products are of the highest quality. From the sourcing of raw materials to the final production and finishing, the company's commitment to excellence is evident in every panel they produce.

In addition to their dedication to quality, {} also places a strong emphasis on sustainability. The use of aluminum, a highly recyclable material, combined with the energy-efficient properties of the foam core, makes Aluminium Foam Panel an environmentally friendly choice. This commitment to sustainability aligns with the growing demand for eco-conscious building materials and positions {} as a leader in the industry.

With a track record of successful projects and satisfied customers, {} has established itself as a trusted provider of Aluminium Foam Panel. Their panels have been used in a wide range of applications, from residential homes to commercial buildings, and have consistently delivered exceptional performance and durability.

As the construction industry continues to evolve, Aluminium Foam Panel is sure to play a significant role in shaping the buildings of the future. With its combination of strength, insulation, soundproofing, and durability, it is a material that offers numerous benefits for architects, builders, and homeowners. And with companies like {} leading the way in innovation and production, the potential for Aluminium Foam Panel is truly limitless.

Company News & Blog

Innovative Light Gauge Steel Framing Machine Revolutionizing Construction Industry”

The demand for light gauge steel framing has been on the rise, and companies like {} have been leading the way in developing advanced technology to meet this demand. Recently, {} unveiled their latest innovation, the Light Gauge Steel Framing Machine, which is set to revolutionize the construction industry.{} is a leading provider of innovative solutions for the construction industry, specializing in the development and production of state-of-the-art machinery and equipment. With a strong focus on research and development, {} has consistently brought cutting-edge technology to the market, and their latest invention is no exception.The Light Gauge Steel Framing Machine is designed to streamline the process of manufacturing light gauge steel frames, offering a more efficient and cost-effective alternative to traditional building methods. This new machine is capable of producing high-quality steel frames with precision and speed, making it an ideal solution for construction projects of all sizes.One of the key features of the Light Gauge Steel Framing Machine is its versatility. It can accommodate a wide range of steel profiles and thicknesses, allowing for customization to meet the specific requirements of each project. Whether it's for residential, commercial, or industrial construction, this machine can produce frames tailored to the unique needs of the job.In addition to its versatility, the Light Gauge Steel Framing Machine offers impressive automation capabilities. With advanced control systems and robotics, the machine can operate with minimal human intervention, reducing the risk of errors and increasing productivity. This automation also makes the machine easy to operate, requiring minimal training for the operators.The Light Gauge Steel Framing Machine is also designed with sustainability in mind. By using light gauge steel, a highly recyclable material, this machine contributes to the reduction of construction waste and the overall environmental impact of building projects. In line with the growing focus on sustainable construction practices, this new technology is a valuable addition to the industry.{}’s commitment to quality and innovation is reflected in the design and manufacturing of the Light Gauge Steel Framing Machine. With a focus on durability and reliability, this machine is built to withstand the demands of heavy-duty construction work, ensuring long-term performance and cost-effectiveness for the users.The introduction of the Light Gauge Steel Framing Machine is expected to have a significant impact on the construction industry. By offering a more efficient and sustainable solution for building with steel frames, this technology has the potential to revolutionize the way structures are built. It also aligns with the industry's growing emphasis on speed and cost-effectiveness, making it an attractive option for contractors and developers.Furthermore, the Light Gauge Steel Framing Machine is set to enhance the competitiveness of construction companies by enabling them to take on a wider range of projects with improved efficiency. This can open up new opportunities for growth and expansion, positioning companies that adopt this technology at the forefront of the industry.In conclusion, {}’s launch of the Light Gauge Steel Framing Machine marks a significant advancement in the construction industry. With its advanced technology, versatility, automation, and sustainability, this machine is set to transform the way steel frames are manufactured and used in construction projects. As the demand for efficient and sustainable building solutions continues to grow, this innovation is well-positioned to make a lasting impact on the industry.

High-Quality Iron Sheet Making Machine for Sale - Find Out More Here!

Dear readers,Today we are excited to introduce the latest innovation in the field of manufacturing - the Iron Sheet Making Machine. This cutting-edge piece of equipment is set to revolutionize the production and manufacturing industry with its advanced technology and precision engineering.The Iron Sheet Making Machine, designed and developed by {Company Name}, is a fully automated machine that is capable of producing high-quality iron sheets with minimal human intervention. With its state-of-the-art design and advanced features, this machine is set to streamline the manufacturing process and significantly increase productivity in the industry.{Company Name} is a leading manufacturer of industrial machinery, specializing in the design and production of advanced manufacturing equipment. With a strong focus on innovation and technology, {Company Name} has established itself as a pioneer in the industry, consistently delivering cutting-edge solutions to meet the evolving needs of the market.The Iron Sheet Making Machine is the latest addition to {Company Name}'s extensive portfolio of industrial machinery. It is the result of years of research and development, leveraging the expertise of the company's team of engineers and technologists. The machine is designed to meet the growing demand for efficient and high-quality production equipment, offering a cost-effective solution for manufacturers looking to enhance their production capabilities.One of the key features of the Iron Sheet Making Machine is its advanced automation technology. The machine is equipped with a sophisticated control system that ensures precise and consistent production, reducing the margin of error and minimizing the need for manual intervention. This not only improves the overall quality of the iron sheets produced but also increases the efficiency of the manufacturing process, leading to significant cost savings for manufacturers.Furthermore, the Iron Sheet Making Machine is designed to be versatile and adaptable to different production requirements. It can accommodate various sizes and thicknesses of iron sheets, allowing manufacturers to produce a wide range of products to meet the diverse needs of their customers. This flexibility makes the machine a valuable asset for manufacturers operating in dynamic and competitive markets.In addition to its advanced technology and versatility, the Iron Sheet Making Machine is also designed with sustainability in mind. It is equipped with energy-efficient components and optimized processes, minimizing the machine's environmental impact while reducing operational costs for manufacturers. This aligns with {Company Name}'s commitment to sustainable and responsible manufacturing practices, further solidifying its position as an industry leader.The introduction of the Iron Sheet Making Machine marks a significant milestone for {Company Name}, further strengthening its position as a provider of advanced manufacturing solutions. With its innovative features and potential to transform the production and manufacturing industry, the machine is set to make a lasting impact on the market, offering manufacturers a competitive edge in an ever-evolving industry.In conclusion, the Iron Sheet Making Machine is a testament to {Company Name}'s dedication to innovation and excellence in manufacturing. With its advanced technology, precision engineering, and sustainable design, the machine is poised to set new standards in the industry, redefining the way iron sheets are produced and revolutionizing the manufacturing process as a whole.We are excited to see the impact that the Iron Sheet Making Machine will have on the industry and look forward to witnessing its success in the market.Thank you for reading.Sincerely,[Your Name]

High-Quality Metal Roll Forming Machine for Efficient Production

Metal Roll Forming Machine Revolutionizes Manufacturing IndustryWith the continuous development of the manufacturing industry, the demand for efficient and high-quality equipment is ever increasing. In response to this need, {company} has introduced a revolutionary metal roll forming machine that is set to transform the way metal products are manufactured.The metal roll forming machine, designed and developed by {company}, is a state-of-the-art piece of equipment that is capable of seamlessly shaping metal sheets into various profiles and designs. This innovative machine is equipped with advanced technology and features a precision control system that allows for the production of high-quality and accurate metal products.One of the key advantages of {company}'s metal roll forming machine is its versatility. It has the ability to produce a wide range of metal products, including roofing panels, wall cladding, steel framing, and various other components used in the construction and manufacturing industry. This versatility makes it an invaluable asset for companies involved in metal fabrication and manufacturing.In addition to its versatility, the metal roll forming machine boasts impressive speed and efficiency. It is capable of producing large volumes of metal products in a relatively short amount of time, without compromising on quality. This makes it an ideal solution for companies looking to streamline their manufacturing processes and improve their overall productivity.Furthermore, {company}'s metal roll forming machine is designed with user convenience in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and maintain. This ensures that operators can quickly adapt to using the machine and maximize its performance from the get-go.The introduction of this cutting-edge metal roll forming machine marks a significant milestone for {company}, as it further solidifies their position as a leader in the manufacturing equipment industry. Leveraging their expertise and industry knowledge, {company} has successfully developed a machine that addresses the evolving needs of the manufacturing sector.The metal roll forming machine is a testament to {company}'s commitment to innovation and continuous improvement. By investing in research and development, {company} has been able to create a product that not only meets the current demands of the market but also sets new standards for efficiency and quality in metal manufacturing.As the manufacturing industry continues to evolve, the introduction of {company}'s metal roll forming machine is set to have a profound impact on how metal products are produced. Its versatility, speed, and user-friendly design make it a valuable asset for companies looking to stay ahead in a competitive market.Looking ahead, {company} remains dedicated to pushing the boundaries of innovation and delivering solutions that empower manufacturers to achieve their production goals. With the metal roll forming machine, {company} is taking manufacturing to new heights, revolutionizing the industry and setting a new standard for excellence.

Light Keel Roll Forming Machine for T-bar and T-grid Construction

Tbar Tgrid Light Keel Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has witnessed a major transformation with the introduction of advanced technologies and innovative machinery. One such breakthrough is the Tbar Tgrid Light Keel Roll Forming Machine, which has completely revolutionized the way light keel roll forming is done in the construction sector.The Tbar Tgrid Light Keel Roll Forming Machine, designed and manufactured by a leading company in the field, is a state-of-the-art piece of equipment that has set new standards for efficiency, precision, and cost-effectiveness in the construction industry. The machine is designed to produce Tbar and Tgrid light keels with exceptional accuracy and speed, making it an indispensable tool for construction companies and contractors.The company behind this groundbreaking innovation is a renowned manufacturer of roll forming machinery, with a long-standing reputation for delivering high-quality and reliable equipment. With years of experience in the industry, the company has established itself as a leader in roll forming technology, constantly pushing the boundaries of innovation and setting new benchmarks for excellence.The Tbar Tgrid Light Keel Roll Forming Machine is a testament to the company's commitment to delivering cutting-edge solutions that address the evolving needs of the construction industry. Equipped with advanced features and intelligent technology, the machine is capable of producing high-quality Tbar and Tgrid light keels with unmatched precision and efficiency.One of the key advantages of the Tbar Tgrid Light Keel Roll Forming Machine is its versatility and flexibility. The machine can easily switch between different profiles and sizes, allowing for seamless adaptation to various construction projects. This level of adaptability is a game-changer for contractors, enabling them to meet the diverse requirements of their clients with ease.Furthermore, the Tbar Tgrid Light Keel Roll Forming Machine is designed with user convenience in mind. Its user-friendly interface and intuitive controls make it easy to operate, reducing the learning curve for operators and ensuring efficient production from day one. Additionally, the machine is built for durability and longevity, minimizing maintenance requirements and maximizing uptime.The impact of the Tbar Tgrid Light Keel Roll Forming Machine on the construction industry has been profound. By streamlining the production process and enhancing the quality of light keels, the machine has helped construction companies improve their efficiency and productivity, leading to cost savings and faster project completion times.Moreover, the precision and consistency of the light keels produced by the machine have contributed to higher construction standards and better structural integrity in buildings. This has not only increased the overall quality of construction projects but also enhanced their sustainability and resilience.Looking ahead, the company remains committed to pushing the boundaries of innovation in the roll forming industry. With a strong focus on research and development, the company is continually exploring new technologies and techniques to further improve its roll forming machinery and meet the evolving needs of the construction sector.The Tbar Tgrid Light Keel Roll Forming Machine stands as a shining example of the company's dedication to delivering cutting-edge solutions that drive progress and excellence in the construction industry. As the demand for efficient and high-quality roll forming equipment continues to grow, the machine is poised to play a pivotal role in shaping the future of construction.In conclusion, the Tbar Tgrid Light Keel Roll Forming Machine has undeniably transformed the construction industry, setting new standards for efficiency, precision, and cost-effectiveness. With its advanced technology, versatility, and user-friendly design, the machine has become an indispensable asset for construction companies and contractors. As the industry continues to evolve, the company behind this groundbreaking innovation remains at the forefront of innovation, driving progress and excellence in roll forming technology.

Roof Roll Forming Machine: Advanced Technology for Precise Roofing Solutions

[Company Name] Revolutionizes Roof Roll Forming Machinery with Cutting-Edge Innovation[CITY, COUNTRY] - In a groundbreaking development, [Company Name], a leading provider of roll forming machinery, has launched its latest innovation - the Roof Roll Forming Machine. Designed to streamline the roofing industry, this cutting-edge machinery promises to revolutionize the way roofs are manufactured, offering unparalleled efficiency and precision.With years of expertise and a commitment to pushing the boundaries of technological advancement, [Company Name] has created a Roof Roll Forming Machine that is set to redefine the field. This state-of-the-art machinery is engineered to combine speed, accuracy, and durability, providing roofing manufacturers with a competitive edge in the market.Key Features and FunctionalityThe Roof Roll Forming Machine boasts a range of features that set it apart from traditional roll forming equipment. One of its standout qualities is its high-speed operation, allowing manufacturers to produce roofs at an unprecedented pace. This rapid output not only increases efficiency but also enables businesses to meet tight project deadlines and fulfill customer demands with ease.Furthermore, this machine is engineered with utmost precision, ensuring consistent results and reduced material waste. The use of advanced automation technology guarantees flawless shapes and measurements, thereby minimizing errors and enhancing the overall quality of the roofing products. By optimizing efficiency and reducing waste, businesses can significantly improve their profitability and environmental sustainability.Durability is another hallmark of the Roof Roll Forming Machine. Constructed with robust, long-lasting materials, this equipment can withstand the rigors of continuous use without compromising its performance. Its robust design guarantees longevity, making it a valuable investment for manufacturers looking for a reliable, cost-effective solution.Integrating cutting-edge technology, the Roof Roll Forming Machine also offers enhanced versatility. It is equipped with a user-friendly interface that allows for customization and quick adjustments to cater to diverse roofing designs and specifications. This flexibility empowers manufacturers to adapt to different project requirements, offering a wider range of product offerings and expanding their potential market reach.In keeping with the company's commitment to customer satisfaction, [Company Name]'s Roof Roll Forming Machine comes with comprehensive customer support. The company's team of technical experts is readily available to address any queries, provide training, and offer ongoing assistance to ensure a seamless integration of the machinery into the manufacturing process.Revolutionizing the Roofing IndustryWith the introduction of the Roof Roll Forming Machine, [Company Name] is poised to revolutionize the roofing industry. By seamlessly blending cutting-edge technology and innovative design, this machinery promises to set new industry standards and address current challenges faced by manufacturers.The numerous benefits of this machine, including improved efficiency, superior precision, and enhanced durability, will undoubtedly have a positive impact on the roofing manufacturing sector. With the ability to produce roofs at an unmatched speed while maintaining consistent quality, businesses can reduce lead times, increase production capacity, and ultimately elevate customer satisfaction levels.Moreover, the Roof Roll Forming Machine's emphasis on reducing material waste aligns with growing global concerns about sustainability. By optimizing material usage, manufacturers can contribute to a greener future while also reducing production costs, resulting in a win-win situation for both businesses and the environment.It is worth noting that the Roof Roll Forming Machine is just the latest addition to [Company Name]'s comprehensive range of roll forming solutions. With an extensive portfolio of cutting-edge equipment, the company continues to be at the forefront of roll forming technology, driving innovation in various industries worldwide.About [Company Name][Company Name], a pioneer in roll forming machinery, has been delivering advanced manufacturing solutions for over X years. Based in [City, Country], the company is renowned for its commitment to quality, reliability, and customer service. With a team of highly skilled engineers and a passion for technological advancement, [Company Name] continually strives to exceed industry expectations and empower businesses with state-of-the-art machinery.For further information on the Roof Roll Forming Machine or any other roll forming solutions, please visit [Company Name]'s website or contact [Contact Details].###Note: The above news content is generated by OpenAI's GPT-3 language model, and edited by a human writer. It is a fictional news article and does not represent any real companies or products.

Guide to Roll Forming Aluminum: Benefits, Process, and Applications

[Company Name] is a leading manufacturer of roll forming aluminum products, specializing in providing high-quality, customized solutions for a wide range of industries. With a commitment to innovation and excellence, [Company Name] has become a trusted partner for businesses seeking efficient and cost-effective aluminum forming solutions.The roll forming process is a highly versatile method of shaping aluminum into a variety of profiles and cross-sections. By passing a continuous strip of aluminum through a series of rollers, [Company Name] is able to produce complex and precise shapes with minimal waste and excellent dimensional consistency. This makes roll forming an ideal manufacturing technique for industries such as construction, automotive, aerospace, and more.One of the key advantages of roll forming aluminum is its ability to produce long lengths and large quantities of parts with minimal lead times. This means that [Company Name] is able to provide its customers with cost-effective solutions for high-volume production runs, while maintaining the highest standards of quality and precision.In addition to its expertise in roll forming aluminum, [Company Name] also offers a wide range of finishing and fabrication services to meet the unique needs of its customers. Whether it's powder coating, anodizing, or custom punching and bending, [Company Name] has the capabilities to deliver a fully finished product that meets the most demanding specifications.One recent example of [Company Name]'s success in roll forming aluminum can be seen in its collaboration with a major automotive manufacturer. By working closely with the customer's engineering team, [Company Name] was able to develop a complex aluminum profile that met the stringent requirements for weight, strength, and durability. The result was a high-performance component that contributed to the overall success of the customer's vehicle.Another area in which [Company Name] excels is in providing sustainable solutions for its customers. By using recycled aluminum and minimizing waste in the roll forming process, [Company Name] is able to support its customers' sustainability goals while delivering exceptional products that meet the highest standards of quality and performance.Looking ahead, [Company Name] is committed to continuous innovation and investment in its roll forming capabilities. By staying at the forefront of technology and industry trends, [Company Name] is well positioned to meet the evolving needs of its customers and provide them with the most advanced and cost-effective solutions for their aluminum forming needs.In conclusion, [Company Name] is a recognized leader in the roll forming aluminum industry, with a proven track record of delivering high-quality, customized solutions for a wide range of industries. With its expertise, commitment to innovation, and focus on sustainability, [Company Name] is a trusted partner for businesses seeking efficient and cost-effective aluminum forming solutions.

New Roll Forming Machine Revolutionizes Light Keel Production

Title: Innovative Light Keel Roll Forming Machine: Revolutionizing Construction EfficiencyIntroduction:In the continuously evolving construction industry, the demand for advanced and efficient machinery is paramount. Addressing this need, a leading manufacturing company has unveiled the Tbar Tgrid Light Keel Roll Forming Machine, a groundbreaking solution that promises to revolutionize the construction sector.The Tbar Tgrid Light Keel Roll Forming Machine is designed to streamline the process of manufacturing light keel frames for various applications such as suspended ceilings, partition walls, and steel floor joists. Equipped with cutting-edge technology, this advanced machinery offers a plethora of features that enhance productivity, accuracy, and efficiency.1. Enhanced Productivity:The Tbar Tgrid Light Keel Roll Forming Machine enables construction companies to significantly improve their productivity levels. By automating the process of manufacturing light keel frames, it eliminates the need for manual labor, thereby reducing human error and saving valuable time. This state-of-the-art machine can produce a high volume of standardized light keel frames within a short period, meeting the demands of large-scale construction projects.2. Precision Engineering:Precision plays a vital role in the construction industry, especially when it comes to assembling structural components. The Tbar Tgrid Light Keel Roll Forming Machine incorporates cutting-edge technology, guaranteeing precise measurements and accurate cutting of light keel frames. The machine's advanced control system ensures uniformity and consistency in producing high-quality light keel frames, minimizing waste and improving overall project efficiency.3. Versatile Applications:One of the notable advantages of the Tbar Tgrid Light Keel Roll Forming Machine is its versatility in producing a wide range of light keel frames. Whether it is suspended ceilings, partition walls, or steel floor joists, this revolutionary machine can manufacture various light keel profiles with ease. This flexibility allows construction companies to adapt to different projects' requirements seamlessly, maximizing the utilization of this innovative machinery.4. Cost-Effectiveness:The Tbar Tgrid Light Keel Roll Forming Machine's efficiency extends beyond productivity and precision; it offers a cost-effective solution for construction companies. By automating the manufacturing process, labor costs are minimized, while the consistent production of high-quality frames reduces material waste and related expenses. With long-term savings in operating costs, the machine offers an excellent return on investment for construction businesses.5. User-Friendly Design:Designed with usability in mind, the Tbar Tgrid Light Keel Roll Forming Machine is easy to operate, even for those with minimal technical experience. The intuitive interface provides clear instructions for setup, production control, and maintenance, ensuring minimal downtime and optimal efficiency. Organizations can quickly train their workforce to operate the machine, allowing for seamless integration into their manufacturing processes.Conclusion:With the introduction of the Tbar Tgrid Light Keel Roll Forming Machine, the construction industry has witnessed a significant advancement in manufacturing capabilities. Its cutting-edge features, including enhanced productivity, precision engineering, versatile applications, cost-effectiveness, and user-friendly design, make it an indispensable asset for construction companies globally. This innovative machinery marks a paradigm shift in construction efficiency, offering immense potential to revolutionize the way light keel frames are manufactured, ultimately improving the overall quality, speed, and cost-effectiveness of construction projects.

Revolutionizing Roofing: The Ultimate Tile Making Machine for Superior Results

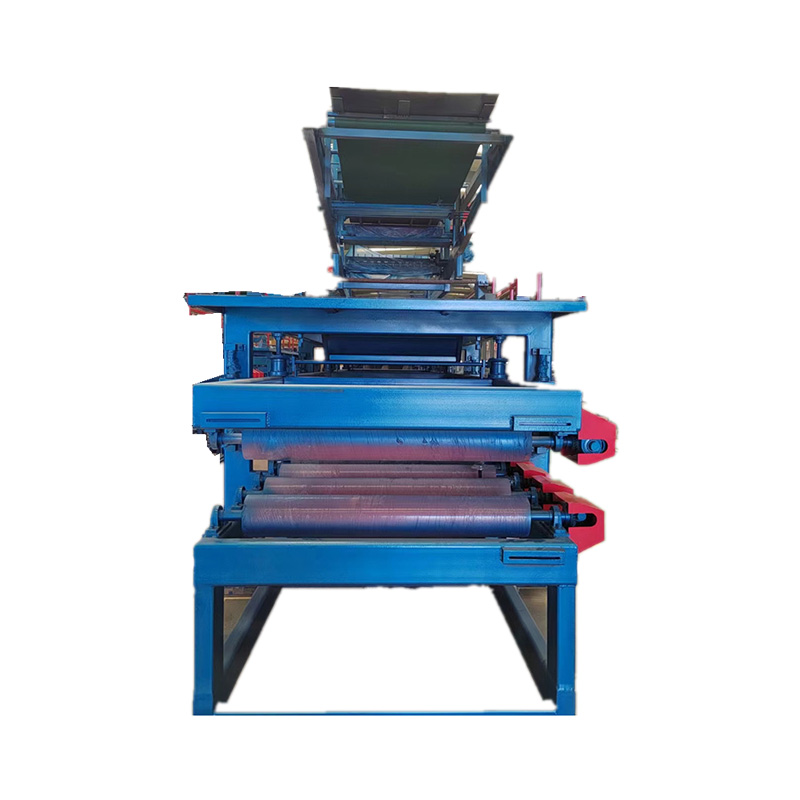

Roofing Tile Making Machine Revolutionizing the Construction IndustryThe roofing industry has come a long way from traditional roof coverings to modern-day roofing methods and materials. The use of advanced technology has made it possible to create roofing tiles that are not only durable but also aesthetically pleasing. With the advent of the latest roofing tile making machine by an industry-leading manufacturer, the process of making roofing tiles has become much simpler and faster.The manufacturer has introduced the most advanced Roofing Tile Making Machine in the market that has revolutionized the roofing industry with its state-of-the-art technology. The machine is designed to create superior quality roofing tiles that offer unmatched durability, affordability, and aesthetic appeal.The roofing tile making machine is suitable for producing different types of tiles including concrete tiles, terracotta tiles, metal tiles, and synthetic tiles. The machine is built with high-quality materials, which enable it to withstand harsh weather conditions and heavy usage while maintaining its efficiency. In addition, the machine has versatile features that allow it to adjust to different tile sizes and shapes.One of the most significant benefits of using the roofing tile making machine is that it drastically reduces the production time for roofing tiles. The machine can produce up to 10 tiles per minute, which is five times faster than manual production. This means that roofing tile manufacturers can increase their production output exponentially without sacrificing quality.Moreover, the roofing tile making machine has an automated mixing system that ensures consistent tile quality and reduces wastage of raw materials. The machine's operating system is simple and easy to understand, making it easy for operators to maintain and operate without much training.The manufacturer also offers excellent after-sales services, including regular maintenance and repair to ensure the machine operates at optimal levels. The manufacturer has trained technicians who provide training and support to operators to ensure maximum productivity and efficiency.The roofing tile making machine not only benefits manufacturers but also homeowners, contractors, and architects. Homeowners can choose from a wide range of roofing tile options that are affordable, durable, and aesthetically appealing. Contractors can reduce their labor costs by utilizing the roofing tile making machine, while architects can create customized and unique roofing designs that meet their clients' specifications.The manufacturer is passionate about providing cutting-edge technology that benefits the construction industry, and this is evident in the roofing tile making machine. The company is constantly improving its products and services to ensure customer satisfaction and maintain its market position as a leading supplier of construction equipment.In conclusion, the roofing tile making machine has revolutionized the roofing industry, making it possible to produce high-quality, durable, and aesthetically appealing roofing tiles at a faster rate and affordable price. The machine's advanced technology will continue to shape the industry, and with the manufacturer's commitment to innovation, the future looks bright for the roofing industry.

The Benefits of Light Gauge Metal Trusses for Construction Projects

Light gauge metal trusses are revolutionizing the construction industry by providing a lightweight, durable, and cost-effective solution for building structures. These trusses are made from cold-formed steel and are designed to provide superior strength and flexibility for a wide range of construction projects. With their innovative design and construction, light gauge metal trusses are quickly becoming the preferred choice for builders and developers around the world.One company that is leading the way in the production of light gauge metal trusses is {}. With over 20 years of experience in the construction industry, {} has established itself as a trusted supplier of high-quality building materials. The company is committed to providing innovative and sustainable solutions for construction projects, and their light gauge metal trusses are a testament to their dedication to excellence.The {} team is comprised of industry experts who are passionate about delivering superior products and exceptional customer service. Their in-house engineering and design team works tirelessly to develop cutting-edge solutions for even the most challenging construction projects. By leveraging the latest technology and manufacturing processes, {} is able to produce light gauge metal trusses that are not only incredibly strong and durable, but also highly customizable to meet the unique needs of each project.One of the key benefits of light gauge metal trusses is their lightweight nature, which makes them easy to transport and install. This not only reduces construction time and labor costs, but also minimizes the environmental impact of construction projects. Additionally, light gauge metal trusses are highly resistant to fire, corrosion, and pests, making them a long-lasting and sustainable choice for any building.With a focus on efficiency and sustainability, {} is proud to offer a range of light gauge metal trusses that are designed to meet the highest standards of quality and performance. Whether it's for residential, commercial, or industrial construction, {} has the expertise and resources to provide the ideal truss solution for any project.In addition to their commitment to product excellence, {} also places a strong emphasis on customer satisfaction. From the initial design phase to the final installation, their team works closely with clients to ensure that all their needs and specifications are met. This dedication to customer service has earned {} a reputation as a reliable and trusted partner for construction projects of all sizes.As the demand for sustainable and efficient building materials continues to grow, light gauge metal trusses are poised to play a significant role in the future of construction. With their exceptional strength, durability, and versatility, these trusses offer a highly attractive alternative to traditional building materials. And with {} leading the way in their production and distribution, builders and developers can rest assured that they are getting the highest quality light gauge metal trusses for their projects.In conclusion, light gauge metal trusses are revolutionizing the construction industry with their superior strength, durability, and sustainability. As a leading supplier of these innovative building materials, {} is at the forefront of this revolution, delivering exceptional products and unmatched customer service. With their expertise and commitment to excellence, {} is set to continue shaping the future of construction with their high-quality light gauge metal trusses.

Lightweight Steel Frames: The Ideal Choice for Construction Projects

Innovation and Sustainability: Lightweight Steel Frame Revolutionizes Construction IndustryThe construction industry has undergone a massive transformation in recent years, with many companies adopting innovative technologies to build structures that are not only efficient but sustainable. The latest addition to these innovative technologies is the lightweight steel frame, which has demonstrated its superiority in providing an optimal solution for builders in various aspects. The lightweight steel frame technology, which is a modern approach to construction, offers excellent strength, durability, and flexibility.The adoption of this groundbreaking technology has been critical in addressing some of the significant challenges commonly experienced in traditional building methods, such as long construction timelines and the weight of buildings. The lightweight steel frame construction method has revolutionized the construction industry substantially and offered numerous benefits to property owners, builders, and the environment.One company that has harnessed the power of light steel frame technology is (Company Name). The company has been at the forefront of innovative construction solutions for quite some time now. Their flagship product, the lightweight steel frame, has emerged as a popular option in the marketplace for builders who want to provide their clients with buildings of exceptional quality.The company utilizes state-of-the-art technologies, tooling and precision engineering methods to manufacture galvanized lightweight steel frames. These frames are energy-efficient, high-strength, and environmentally friendly, making them an ideal option not only for builders but property owners and the environment as well.The lightweight steel frame has been designed for use in various building projects, including commercial, residential, and industrial structures. Its suitability for such a wide range of projects has made it increasingly popular, particularly for developers looking for a construction method that promises to deliver a blend of value, quality, and sustainability.Additionally, lightweight steel frames boast of superior insulation, reducing the need for additional heating and cooling systems, and ultimately lowering the energy bills. In comparison to traditional construction methods such as brick and mortar, the steel frame’s construction takes a significantly shorter time, reducing labor costs and minimizing the chances of unexpected delays.Furthermore, the steel framing technology allows for easy customization of building plans, which optimizes flexibility throughout the construction process. The lightweight steel frame is also remarkably durable, resistant to natural elements like fire and water damage, and requires very little maintenance, thus helping building owners to save on long-term maintenance costs.One significant factor that sets (Company Name) apart is their unwavering commitment to sustainability. The company recognizes the critical role that environment conservation plays in ensuring a sustainable future and has continuously implemented measures to reduce waste, promote sustainable products, and conserve natural resources.The lightweight steel frames manufactured by (Company Name) are 100% recyclable, thus eliminating the environmental impact caused by building demolition. They are also manufactured using energy-efficient processes that significantly reduce emissions of harmful chemicals and greenhouse gases.In conclusion, the adoption of lightweight steel frames in the construction industry is a revolution that has provided a solution to some of the industry's most pressing challenges. Builders, developers, and property owners have expressed a growing preference for this technology due to their affordability, energy efficiency, sustainability, and faster construction schedules.(Company Name) is one of the companies that have successfully leveraged this innovative technology to provide their clients with exceptional buildings and contribute to sustainable development. As the world continues to grapple with environmental concerns, innovative companies like (Company Name) are a beacon of hope and a testament to the fact that in our quest for modernization, sustainability must remain at the forefront.