This Light Gauge Steel Framing Machine is for producing the studs and tracks which are used in light gauge steel structure buildings. The studs and tracks which are produced by the Light Gauge Steel Framing Machine are light. The building steel structure can be quickly built without normal heavy tools and equipment. Every component can be easily carried by hand. The main tool is a light, hand-held screw gun. Because the steel is strong, LGS structures are lighter than wood framed structures of equivalent strength. C89 Frame machine, light steel frame steel keel lgs frame roll forming machine,steel frame villa is build by light gauge keel roll forming buildings machine. Light gauge steel structures do not rot, shrink, warp, or decompose like wood structures, and can be used in areas where there is a probability of termite attack. It's already our sixth gerneration lgs framing machine after several years of improvement. We adopt Vertex BD software,And it have a.8 working positions (pipeline hole, web hole, small side cutting, fixed hole, chamfering, web shrinkage hole, shearing, bolt hole, etc.) b.Our lgs framing machine can make comple house sturcture include house wall, roof, window, floor etc. We provide a fully automated light steel frame production line solution integrating hardware and software, with“end-to-end” production from CAD architectural design software to production, construction and installation. meet the need of high standard and precision of the LGSF machine from the light gauge steel frame building construction team.Stud and truck roll forming machine glazed tile roll forming machine roof panel roll forming machine1) Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2) Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly. 3) Q: How does your factory do regarding quality control? A: Quality is priority. MACTEC People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4) Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. MACTEC is ALIBAB’s Gold supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers.

This Light Gauge Steel Framing Machine is for producing the studs and tracks which are used in light gauge steel structure buildings. The studs and tracks which are produced by the Light Gauge Steel Framing Machine are light. The building steel structure can be quickly built without normal heavy tools and equipment. Every component can be easily carried by hand. The main tool is a light, hand-held screw gun. Because the steel is strong, LGS structures are lighter than wood framed structures of equivalent strength. C89 Frame machine, light steel frame steel keel lgs frame roll forming machine,steel frame villa is build by light gauge keel roll forming buildings machine. Light gauge steel structures do not rot, shrink, warp, or decompose like wood structures, and can be used in areas where there is a probability of termite attack. It's already our sixth gerneration lgs framing machine after several years of improvement. We adopt Vertex BD software,And it have a.8 working positions (pipeline hole, web hole, small side cutting, fixed hole, chamfering, web shrinkage hole, shearing, bolt hole, etc.) b.Our lgs framing machine can make comple house sturcture include house wall, roof, window, floor etc. We provide a fully automated light steel frame production line solution integrating hardware and software, with“end-to-end” production from CAD architectural design software to production, construction and installation. meet the need of high standard and precision of the LGSF machine from the light gauge steel frame building construction team.Stud and truck roll forming machine glazed tile roll forming machine roof panel roll forming machine1) Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2) Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly. 3) Q: How does your factory do regarding quality control? A: Quality is priority. MACTEC People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4) Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. MACTEC is ALIBAB’s Gold supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers.

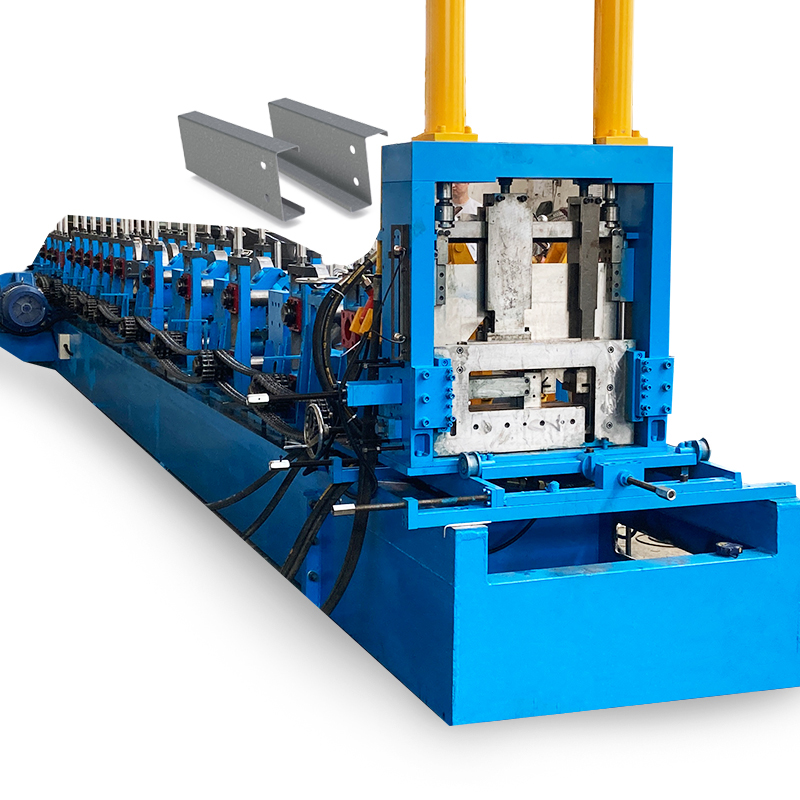

| Light Gauge Steel Framing Roll Forming Machine | |

| Feeding material | G300-G550 zinc plated, aluminum-zinc plated coil |

| Thickness | 0.75-1.2mm |

| Maximum speed | 2800m/h |

| Normal production speed | 300-700m/h |

| Main unit power | 7.5KW servo motor,sellf-locking function |

| Voltage | 380V/50Hz/3phase or as customer request |

| Hydraulic power | 5.5KW |

| Inkjet printer | Standard |

| Size | 4.2m*1.0m*1.5m |

| Weight | Approx 3050kg |

Two in one decoiler, Leveling & decoiler in one machine, Save spaceDouble head decoiler is optinal, can bear total 2 tons

Two in one decoiler, Leveling & decoiler in one machine, Save spaceDouble head decoiler is optinal, can bear total 2 tons Punch system, we can customize according to your requirement, this punch molds is special customized for you,below is the punch molds for standard C89 LGS Machine.

Punch system, we can customize according to your requirement, this punch molds is special customized for you,below is the punch molds for standard C89 LGS Machine. Ink printer, two ink cartridges,control by computer,Printed font size can be adjusted.

Ink printer, two ink cartridges,control by computer,Printed font size can be adjusted. Production showing page, shows the production online.Recognized the production file automatically.

Production showing page, shows the production online.Recognized the production file automatically.

corrugated sheet forming machine floor deck roll forming machine CZ Purlin roll forming machine

corrugated sheet forming machine floor deck roll forming machine CZ Purlin roll forming machine

downspout roll forming machine

solar panel support forming machine

double layer roll forming machine

Our lightweight steel framing machines are capable of producing lightweight, durable columns and tracks, ideal for building steel structures quickly and easily. One of the main advantages of our machines is that each component is light and can be easily carried by hand for easy transportation to the construction site. Using our machines, construction teams can forego the traditional heavy tools and equipment typically used on timber structures. Instead, the main tool required is a lightweight, hand-held screw gun. This not only saves construction time, but also reduces the cost and labor required for construction. The strength of steel is essential for building lightweight steel structures. Due to the strength of our posts and tracks, the structure weighs less than wood frame structures. This means our lightweight steel frame machines can reduce construction time while providing a solid foundation for buildings.