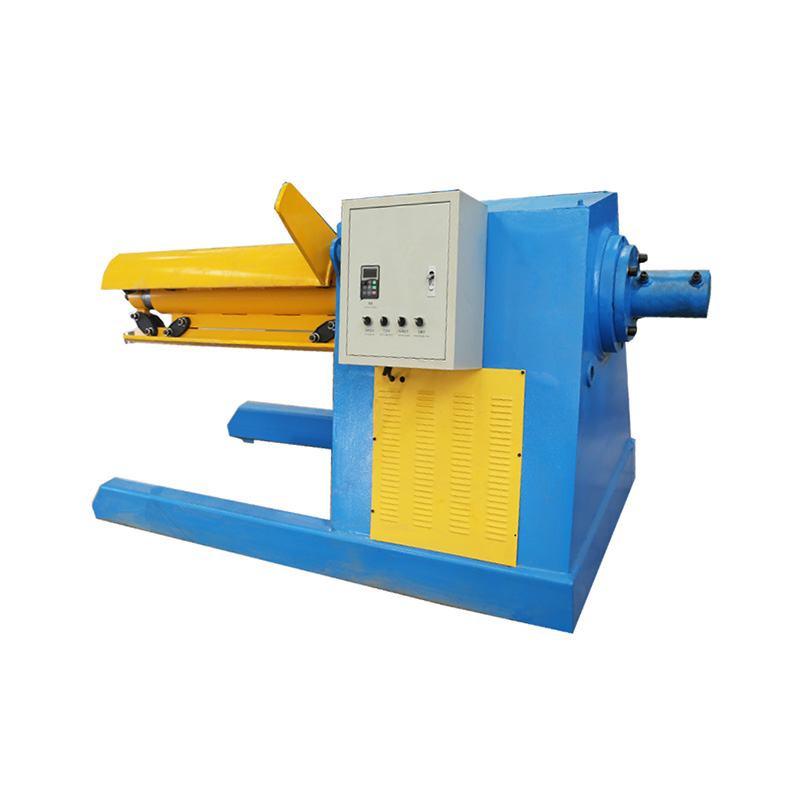

| Decoiler | 1 Set |

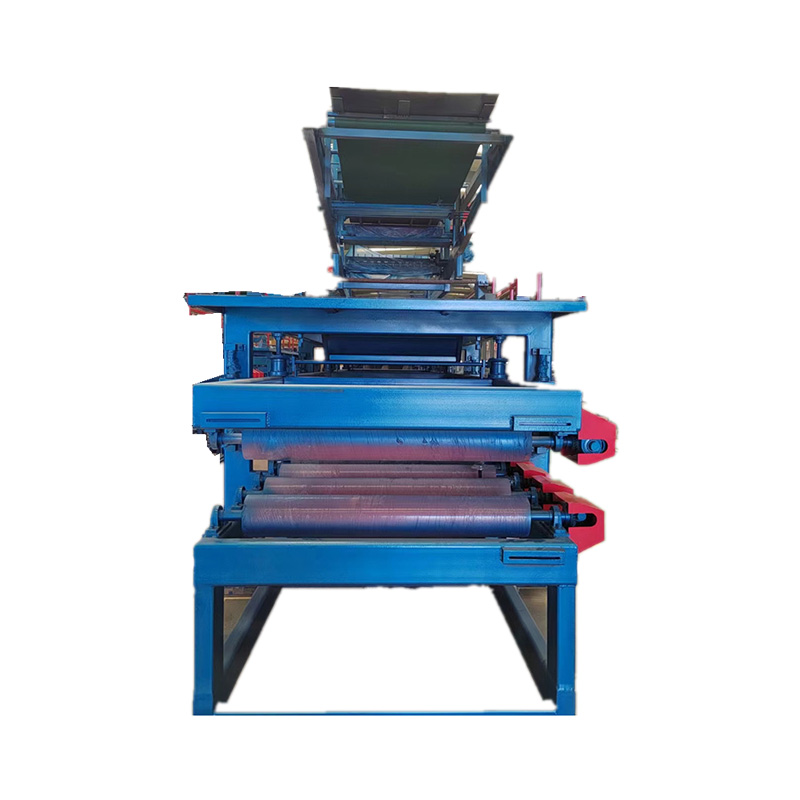

| Guiding Equipment | 1 Set |

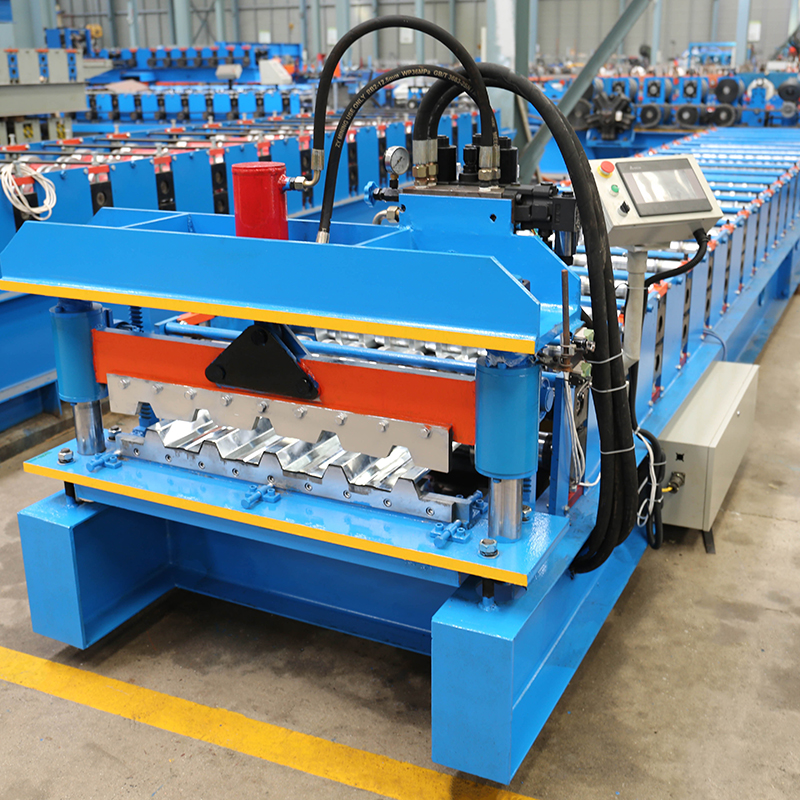

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

This machine is widely used in the production of the roof wall steel construction and so on.

This machine is widely used in the production of the roof wall steel construction and so on.

Q. Will i receive a good machine ? Same with my wanted ? A: Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance. Q. What will you do if the machine is broken? A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment. Q. What is your payment terms? A: 1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping. 2 : We accept 100% L/C at sight 3: We accept Western Union payments. 4: Other payment terms you want to pay, please let me know and i will check and reply you.

Q. Will i receive a good machine ? Same with my wanted ? A: Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance. Q. What will you do if the machine is broken? A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment. Q. What is your payment terms? A: 1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping. 2 : We accept 100% L/C at sight 3: We accept Western Union payments. 4: Other payment terms you want to pay, please let me know and i will check and reply you.| Machine Specifications | |

| Weight | About 3tons |

| Size | About 6.7M* 1.4 M*1.4M(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: your requirement | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils Aluminum alloy steel |

| Thickness | 0.5-1.0 mm Aluminum alloy steel |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 12-14 |

| Diameter of forming rollers shafts | 70mm full solid |

| Roll Forming Speed | 3-5m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5 kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

Lgs framing roll forming machine for villa Automatic C/Z purlin roll forming machine CU Omega L furring channel Roll Forming Machine

Lgs framing roll forming machine for villa Automatic C/Z purlin roll forming machine CU Omega L furring channel Roll Forming Machine Double layer roofing roll forming machine Portable Clip Lock roof forming machine Square downspout pipe roll forming machine

Double layer roofing roll forming machine Portable Clip Lock roof forming machine Square downspout pipe roll forming machine

Deck panel roll forming machine

3mm Slio/ water tank corrugated sheet machine

EPS/rockwoll Z lock sandwich panel line